Risheb Rasheed

Cae , Hypermesh,Ansa

Skills Acquired at Skill-Lync :

- STRUCTURAL-MESHING

- ANSA

- HYPER-MESH

- SHEET-METAL-MESHING

- FEA

- RADIOSS

- CRASH-WORTHINESS

- LS-DYNA

Introduction

51 Projects

Week 3 - 2D meshing for sheet metal

WEEK 3 CHALLENGE AIM To generate the mid surface of the given model and generate a mesh according to the required quality criteria. PROCEDURE Geometry cleanup is performed on each part to check for triple cons, single cons, cracks, unchecked faces, etc after which we can move on to generating the mid surface. Measure the…

10 Apr 2021 05:03 PM IST

Week - 4 - 2D meshing for Plastic components

WEEK 4 CHALLENGE AIM To generate the mid surface of the given model and generate a mesh according to the required quality criteria. PROCEDURE Geometry cleanup is performed on the after which we can move on to generating the mid surface. The thickness of each part is measured and then stored. For midsurface generation,…

04 May 2021 08:53 AM IST

Tool Test 1

off elements in panel model are considered unsolvable due to multiple triple cons near them

10 May 2021 03:19 PM IST

Week- 5 - Solid meshing

WEEK 5 CHALLENGE AIM To generate tetra mesh of the given model using ortho tria and tria elements followed by generating a volumetric mesh according to the required quality criteria. PROCEDURE Geometry cleanup is performed on after which we can move on to tetra meshing. Check Geometry is performed to check for geometrical…

21 May 2021 06:09 AM IST

Tool Test-2

Tool Test 2Unstructured Tetra Fem was used Element Length:3Min Length:1Max Length:5Collapse:0.2

24 May 2021 08:39 AM IST

Week 6 - Creating connection for Rear door

WEEK 6 CHALLENGE AIM To deploy connections on the given FE model for NVH Simulation according to Nastran Deck. PROCEDURE Since we are given the FE model, we deploy independent PIDS to each Pid region. First, we start with the door hinge, we deploy Rbe2 many node connections for rigidity on the hinge and then connect the…

02 Jun 2021 06:12 AM IST

Week - 8 - Morphing

MORPHING AIM To modify the given cad data using the morphing module in Ansa. PROCEDURE To create a new morphing box we go to the morph module and select new under boxes. Then we select the features that we need to morph and middle-click as shown. Once the morphing box is formed we select move under box morphing…

16 Jun 2021 09:19 AM IST

Project 1 - 2D meshing on the instrumental Panel

2D MESHING ON INSTRUMENT PANEL AIM To generate the mid surface of the given model and generate a mesh according to the required quality criteria. PROCEDURE Measure the thickness of each part and store the measurements. Check geometry for errors like unchecked faces,etc. For mid surface generation, manual mid surfacing…

23 Jun 2021 07:36 AM IST

Project - 2 - Meshing on the suspension Assembly

WEEK 6 CHALLENGE AIM To mesh the given rear wheel assembly model, with tetra and 2 D elements, and deploy connections for the components. PROCEDURE It is observed that most components in the model have a very large thickness, so we will proceed with generating a mesh with tetra elements for most of the component. We split…

26 Jun 2021 04:41 PM IST

Week 4-1D Element Creation Challenge

CHALLENGE AIM To mesh the given component with a target element length of 5 units and to create 1 D connections as specified. PROCEDURE First, we create the mid surface of the given component with the auto mid command.Figure1Figure 2 We create new material for steel and assign it the Mat1 card image.Mat1 card gives the…

01 Jul 2021 07:33 AM IST

Week 6-Meshing of Hood Challenge

Week 6 Challenge Aim To create the mid surface of the given component and mesh it according to given criteria. Procedure Determine the thickness of the components using the distance command and assign property thickness Generate the mid surface of each component individually using auto mid command with different component…

11 Jul 2021 12:18 PM IST

Week 8-3D Tetra Meshing Challenge

TETRA MESHING IN HYPERMESH Aim To mesh the given components with tetra elements using various hyper mesh options. Procedure For the first model, we first create a 2d mesh on the surface of the component and then generate a tetra mesh for the component. For meshing, we use normal tria elements for flat surfaces and ortho…

22 Jul 2021 11:13 AM IST

Week 9-Creation of 1D Connectors Challenge

Connectors in Hyper Mesh Aim To mesh the given model according to given criteria and create connections as required. Procedure Criteria for mesh quality is given in table1. S.N Quality Criteria Value 1 Aspect Ratio 5 2 Skewness 45 3 Warping 15 4 Taper 0.5 5 Min. Length 2…

28 Jul 2021 10:22 AM IST

Week 12:Project 2-Meshing of Rear Wheel Holder challenge

Meshing Of Rear Wheel Holder Aim To mesh the given rear wheel holder model according to the given criteria Procedure It can be observed that the given model has a lot of free edges on the surface. Figure 1 These free edges can be solved if they are simple but if it is a tedious process, it can be faster to simply ignore…

04 Aug 2021 09:49 AM IST

Week 12:Project-1-Meshing of Door Inner Panel Challenge

Side Door Aim To mesh the given side door model according to the given criteria Procedure Before we can mesh the model, it is necessary to prepare the mid surface of the given model As this is a model with several surfaces having a varying thickness, we will need to manually extract the mid surface for several components…

14 Aug 2021 03:51 PM IST

Assignment 1-2D Meshing Challenge

Assignment 1 Aim To create and mesh the mid surface of the given models Procedure It is mentioned that holes less than 5mm in Diameter can be ignored. Criteria given in Table 1 Min Length 3.5 Max Length 7 Holes<5mm in dia can be ignored` So in parameter file settings if we change the range to 2.5 mm on…

25 Aug 2021 10:30 AM IST

Assignment 2-RADIOSS Engine File Editing & 3D Meshing Challenge

Assignment 2 Objective To 3D mesh the given components To modify the .rad file and calculate timestep Procedure Given Density =0.0078 g/mm3 Youngs Modulus E=210Gpa Speed of Sound = `sqrt (E/rho)` Applying the values to the formula above, we get the speed of sound as 164.08 mm/s The length of the rail is 1000mm The…

27 Aug 2021 11:01 AM IST

Assignment 3-2D Element Formulation Challenge

Assignment 3 Aim To compare the results of simulation before and after property assignment for the given crash beam file Procedure Import the .rad file to hypermesh Figure 1 Change the tstart to 25 ms in Eng_Anim_Dt and Tstop in Eng_Run to 55ms Figure 2 Figure 3 After making the changes,export the file to a separate…

30 Aug 2021 11:17 AM IST

Assignment 4-RADIOSS Material Laws Challenge

Assignment 4 Aim To compare and analyze the rupture plate simulation using different material properties Procedure Import the failurejohnson_000.rad file to hypermesh Figure 1 After this, export the file to a new folder Figure 2 An alternative is to simply name the file appropriately with a _0001.rad end so that radioss…

01 Sep 2021 01:08 PM IST

Assignment 5-RADIOSS Interfaces & Study of Effect of Notches Challenge

Assignment 5-RADIOSS Interfaces & Study of Effect of Notches Challenge Aim To mesh the given model with a mesh size of 6mm To create different interfaces with recommended properties and compare the simulation results Theory Interfaces are defined to model how parts interact when they come in contact with each other…

08 Sep 2021 09:42 AM IST

Frontal Crash Simulation

Project 1 Front Crash Simulation Aim Frontal crash simulation of the given Fe Biw Neon Model using Hypermesh/Radioss Solver. Setup Requests Check unit system and either follow[Mg mm s] or [Kg mm ms]. Create appropriate interface ,friction 0.2 and recommended parameters. Make sure of no penetrations and intersection. Correct…

01 Nov 2021 01:30 PM IST

Side Pole Crash Simulation Challenge

Side Crash Simulation Aim To perform side crash analysis on the given Dodge neon Biw model using Hypermesh and Radioss solver. Setup Request Check unit system and either follow [Mg mm s] or [Kg mm ms]. Create an appropriate interface ,friction 0.2 and recommended parameters. Make sure of no penetration and intersections.…

01 Nov 2021 01:35 PM IST

Week - 1 - Consistency of Units

Challenge 1 Objective: To convert the given values from Si units to various other unit systems Solution Value of the following measurements are given as follows: MASS 1kg LENGTH 1m TIME 1s FORCE 1N STRESS 1Pa ENERGY 1Nm DENSITY 1Kg/m3 YOUNG'S Modulus 210GPa Velocity 56.33KMPH GRAVITY 9.8m/s2 Conversion From…

22 Sep 2021 07:17 AM IST

Week - 2 - Explicit and Implicit Analysis

Challenge 2 Aim: To solve the equation, F(u)= u3+9u2+4u, using Implicit and Explicit Methods. Theory Implicit Analysis One method of solving for the unknowns {x} is through matrix inversion (or equivalent processes). This is known as an implicit analysis. When the problem is nonlinear, the solution is obtained in…

24 Sep 2021 12:12 PM IST

Week - 3 Drop test Challenge

Drop Test Aim To perform a simple drop test simulation on the given model Objective To create all the necessary keyword files for a basic simulation in ls Dyna Theory Element Formulation Element formulation deals with derivations needed to deduce displacements acting on a body when discretized by finite elements.…

27 Sep 2021 02:35 PM IST

Week - 4 - Crash Box Simulation

Crash Box Objective To simulate a crash test on the given simple crash box component Conditions - Material for the crash box is steel. The simulation needs to be started using elastic material to verify its correctness and later a nonlinear material card data will be provided. The thickness of the crash box is 1.2mm.…

29 Sep 2021 12:06 PM IST

Week - 5 - Modelling Spotwelds

SpotWelds Objective To simulate a crash test on the given assembly of components and compare the difference in using solid and 1D beam elements for spot Weld Conditions - Material for the assembly is steel - Initial velocity for the assembly should be around 50 kmph - The units system to be used is gm-mm-ms …

04 Oct 2021 02:03 PM IST

Week-6 Calculate the Stretch Ratio by comparing the ELFORM (-2,-1,1,2) with Ogden_Material Model.

Odgen Material Model Objective To simulate a tensile test on a 10x10x10mm cube using the given Ogden material card and compare the difference in using Elform 1,-1,2 and -2 property. Condition - Stretch Ratio of at least 5 should be achieved - The units system to be used is gm-mm-ms Deliverables:…

11 Oct 2021 01:39 PM IST

Head Impact

Head Impact Objective To simulate a head impact test and calculate Head Impact Criterion for the following cases: Simple Head Model and rigid wall Pedestrian Headform Model and rigid wall Pedestrian Headform model and meshed hood model Deliverables: The impact simulation of a simple head impact with the Rigid wall. The…

01 Nov 2021 01:48 PM IST

Week - 8 Mass Scaling

Mass Scaling Aim To understand the effect of mass scaling on simulation run time and stability in Ls Dyna The difference in the explicit and implicit analysis of the same simulation Theory Mass-scaling refers to a technique whereby nonphysical mass is added to a structure to achieve a larger explicit timestep. Anytime…

21 Oct 2021 01:28 PM IST

Week - 9 Material Modeling from Raw Data

Material Modelling Objective To derive the data from the given stress vs strain curve Model the given tensile test specimen according to the derived data and compare the stress vs strain curves Condition - the elastic modulus is 20.9E+06 psi. or 114.1 GPa - The units system to be used is kg-mm-ms …

25 Oct 2021 09:30 AM IST

Week - 10 Hyperelastic Material Models

Hyperelastic Material Modelling Objective To compare data from the given engineering stress vs engineering strain for a hyperelastic material to the fitted data. Condition - Vary the constant n=1,233 for hyperelastic and Ogden material model. - The units system to be used is kg-mm-ms Theory The hyperelastic…

27 Oct 2021 08:46 AM IST

week-11 Joint creation and Demonstration

JOINTS Aim To create translational, revolute, spherical and cylindrical joints for rigid and deformable bodies using Ls-Dyna. Theory Revolute Joint. Nodes 1 and 2 are coincident; nodes 3 and 4 are coincident. Nodes 1 and 3 belong to rigid body A; nodes 2 and 4 belong to rigid body B. The relative motion of the two rigid…

28 Oct 2021 03:06 PM IST

Bird Strike - Project - 2

BIRD STRIKE Aim: To perform bird strike test on the given engine model Theory Bird strike A bird strike is strictly defined as a collision between a bird and an aircraft that is in flight or on a takeoff or landing roll. The term is often expanded to cover other wildlife strikes - with bats or ground animals.…

03 Nov 2021 05:38 AM IST

Week 1 Stress Concentration on a Plate with hole

Stress Concentration on a Plate with hole Objective To compare the deformations on a simple steel plate with a single hole to that with smaller holes for stress concentration control Procedure Create a new static structural project in workbench Make sure structural steel is selected in engineering data Create the…

16 Nov 2021 02:19 PM IST

Week 1 Spur Gear Challenge

SPUR GEARS Aim: To set up a simple spur gear system using 3 different materials , Bronze cast iron and cast steel, and determine the best material to proceed with for manufacture Theory Spur Gears Spur gears are one of the most popular types of precision cylindrical gears. These gears…

18 Nov 2021 09:01 AM IST

Week 2 Bevel Gear Challenge

GRID DEPENDENCY TEST ON BEVEL GEAR Aim To model a simple bevel gear system and perform grid dependency test at mesh size of 6mm ,5mm and 4mm. Theory Bevel gears are power transmission parts first employed to modify the direction of shaft rotation and to reduce the speed and improve the…

20 Nov 2021 01:47 PM IST

Week 2 Railwheel and Track

Railwheel and Track Aim To setup a given railwheel and track model to check for deformation,strain and life under 2 different loads Theory A train wheel or rail wheel is a type of wheel specially designed for use on railway tracks. The wheel acts as a rolling component, typically pushed onto an axle and mounted directly…

23 Nov 2021 02:05 PM IST

Week 3 Sheet metal Bending challenge

SHEET METAL BENDING Aim To setup a given sheet metal bending process and compare the difference using 3 material models. Theory Bending is one of the most common sheet metal fabrication operations. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular…

26 Nov 2021 09:55 AM IST

Week 3 Verification of Weld Joints

WELD JOINTS Aim To setup a 3 different types of welding for a load of 15000 and determine the directional deformation, strain and stresses involved Case 1: Weld Material Stainless steel, material of plates and ribs is also stainless steel Case 2:Weld Material: Aluminium wrought alloy, material of plates and ribs is stainless…

27 Nov 2021 08:28 AM IST

Week 4- Rolling operation

SHEET ROLLING Aim To model a simple sheet rolling system and determine the thickness reduction, stresses on sheet metal and deformation. Theory In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness, to make the thickness…

29 Nov 2021 08:43 AM IST

Week 4 -Wire Bending Challenge

WIRE BENDING Aim To model a wire bending system and determine strains and stresses on the wire Theory Wire forming is a method for applying force to change the contour of wire by bending, swaging, piercing, chamfering, shearing, or other techniques. The various techniques for wire forming can produce any type of…

02 Dec 2021 03:12 PM IST

Week 5 Sphere pressing on a plate

SPHERE ON PLATE Aim To model a sphere pressing on plate setup and observe plastic deformation. Procedure Start a new static structural model in ansys and import the model Add the nonlinear materials of structural steel non-linear. Open this model in ansys mechanical. Check that the materials were properly assigned…

04 Dec 2021 10:38 AM IST

Week 5 Bending of iPhone

WIRE BENDING Aim To model a bending of a phone model and determine strains and stresses on the wire Procedure Start a new static structural model in ansys and import the model Add the nonlinear materials of aluminium alloy , general material polyethelene, duplicate it and modify the property to be similar…

12 Dec 2021 01:45 PM IST

Week 8 - Universal Joint

Slider-Crank Aim To model a slider crank system and determine strains and stresses on the clip. Procedure Start a new transient structural model in ansys and import the model Add the materials as shown (for the second case). Open this model in ansys mechanical. Define the…

30 Jan 2022 12:11 PM IST

Week 8 Worm Gear Challenge

Worm Gear Aim To model a worm gear system and determine strains and stresses Procedure Start a new transient structural model in ansys and import the model Open the model in space claim and cut the gear in half so as to meet the academic node and element limits Open…

31 Jan 2022 02:50 PM IST

Week 9 Machining with Planer Challenge

Machining-Planar Aim To model a simple machining model system and determine strains and stresses. Procedure Start a new explicit dynamics model in ansys and import the model Add the materials as shown. Open this model in ansys mechanical. Assign Steel-1006 to the workpiece…

05 Feb 2022 01:19 PM IST

Week 9 Tension and Torsion test challenge

Machining-Planar Aim To model a simple machining model system and determine strains and stresses. Procedure Start a new explicit dynamics model in ansys and import the model Add the materials as shown. Open this model in ansys mechanical. Assign Steel-1006 to the workpiece…

05 Feb 2022 01:43 PM IST

Week 10 Bullet penetrating a Bucket Challenge

Bucket-Bullet Aim To model a simple bucket-bullet system and determine strains and stresses. Procedure Start a new explicit dynamics model in ansys and import the model Add the materials as shown. Open this model in ansys mechanical. Assign Tantalum to the bullet and Aluminium Alloy/Magnesium…

05 Feb 2022 04:01 PM IST

Week 11 Car Crash simulation

Car Crash Aim To model a car crash system and determine strains and stresses. Procedure Start a new explicit dynamics model in ansys and import the model Add the materials as shown. Open this model in ansys mechanical. Assign Stainless steel NL to the car body and a thickness of 0.3mm. (P…

06 Feb 2022 11:24 AM IST

Week 7-Long Piston With Cam

Cam model Aim To model a cam system and determine strains and stresses. Procedure Start a new transient structural model in ansys and import the model Open this model in ansys mechanical. Check that the materials were properly assigned to the model. Set the contact to rename based on definition and select…

26 Feb 2022 11:38 AM IST

5 Course Certificates

HyperMesh for FEA Plastic and Sheet Metal Applications

Crashworthiness Analysis using HyperMesh and Radioss

Introduction to Structural Analysis using ANSYS Workbench

Academic Qualification

B.Tech

Vellore Institute of Technology

10 Jun 2016 - 07 Sep 2020

12th

Chettinad Vidyashram

02 Apr 2015 - 11 May 2016

10th

Chettinad Vidyashram

10 Apr 2013 - 08 May 2014

Here are the courses that I have enrolled

Similar Profiles

Ladder of success cannot be climbed with hands in pocket.

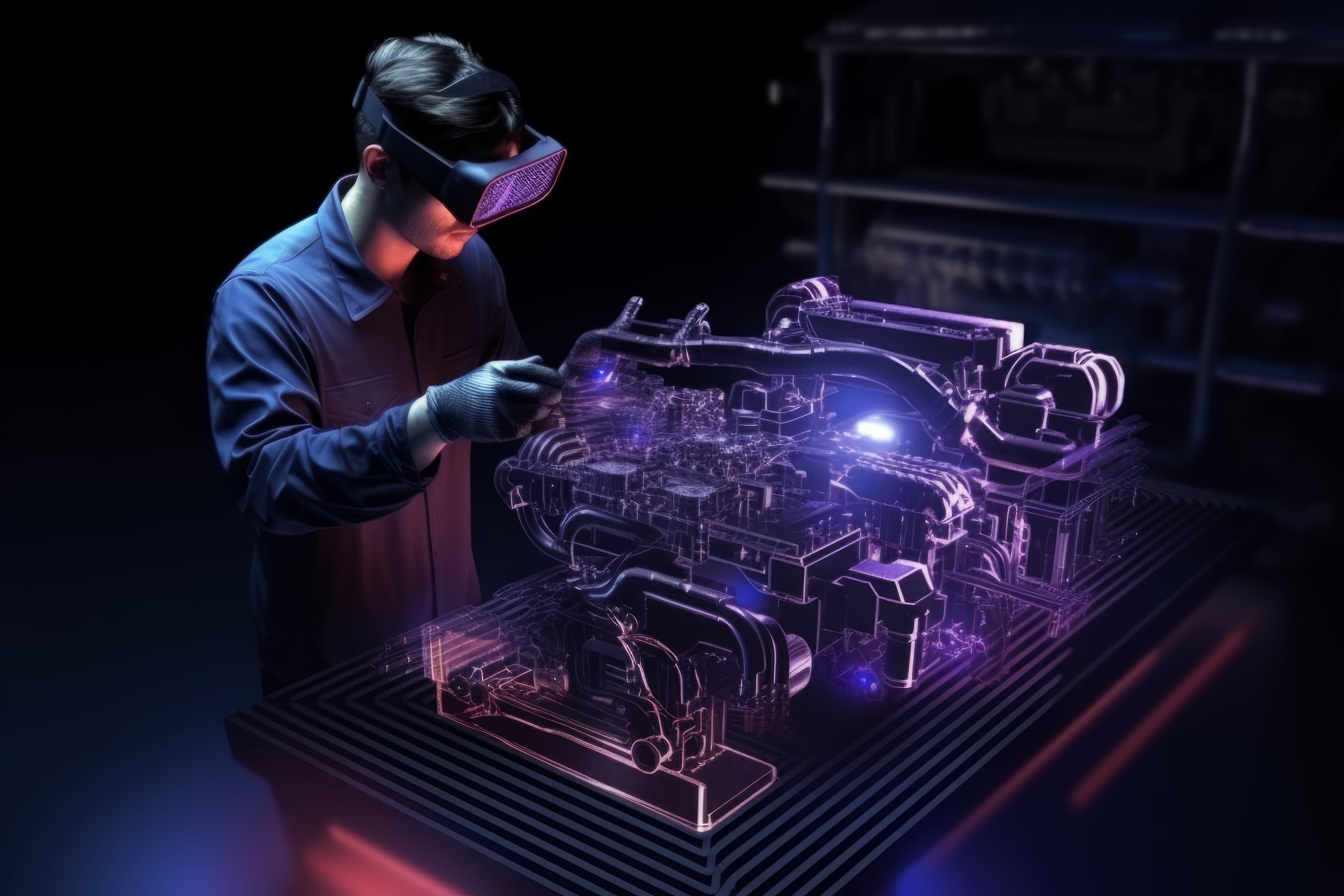

The Future in Motion

Give more than what you get you will get more than what you gave

Avid learner