Madhupavan H

Hungry learner

Skills Acquired at Skill-Lync :

- CATIA

- WIRING-HARNESS-DESIGN

- NX-CAD

- SHEET-METAL-DESIGN

- BIW-DESIGN

- FEA

- LS-DYNA

- DESIGN

Introduction

34 Projects

Wiring harness design in CATIA V5 - 3D modeling Week 2 Challenge

AIM - Define given connectors & Connector clip as Electrical Connector using Electrical Part design Workbench in CATIA V5 OBJECTIVE - The objective of the project is to first , download the given files from TE.com then define them as an electrical connector or equipment & lastly give all the required electrical properties…

13 Jun 2022 03:59 PM IST

Wiring harness routing & packaging Rules Week 3 Challenge

AIM - To solve the above assignment quetions and define the neccessary electrical properties in the respective workbench.OBJECTIVE:To Download the p_clamp cad data & define it as Electrical support using Electrical Part design Workbench & Defining all the necessary properties. To Download the Back shell…

14 Jun 2022 08:56 AM IST

Wiring harness design in CATIA V5 - 3D modeling Week 4 Challenge

AIM: Route the following harness layout in Electrical workbench. Make assumption for harness bundle diameters. Use Following connectors as shown in layout diagram. Add protective covering on all branches connected to DT06-2S & DT06-4S connectors. Keep end extremity at 30mm (from connectors end) DT06-4S…

15 Jun 2022 02:27 PM IST

Wiring harness design in CATIA V5 - 3D modeling Week 5 & 6 Challenge

AIM:Route the following harness layout in Electrical workbench. Make assumption for harness bundle diameters. Use the connectors provided. After completion of routing, Check the bundle Continuity. Add snap of result in submission Add annotation to all connectors. Make an assumptions for annotations like connect 1 , 2 etc…

17 Jun 2022 09:00 AM IST

Wiring harness design in CATIA V5 - 3D modeling Week 7 Challenge

AIM: Flatten the previously done harness assembly which is shown below . Place the flattened view on drawing sheet. Ensure bundles with protective coverings has different visuals on drawing view. SOLUTION : Starting with the product file of previously done wire harness assembly Then nned to ceate new flatten product Open…

20 Jun 2022 04:56 PM IST

Project 1

AIM : Route the Wiring harness on Given Engine and Prepare flatten view drawing in CATIA V5. Application of all Packaging rules, Industry best practices studied in this course shall be demonstrated in design. Apply Protection coverings as required. SOLUTION: Download & Define all the connectors by using following method…

27 Jun 2022 08:59 AM IST

Project 2

AIM : Route the Wiring harness on Given car body and Prepare flatten view drawing in CATIA V5. Application of all Packaging rules, Industry best practices studied in this course shall be demonstrated in design. SOLUTION: Download & Define all the connectors by using following method The following fig shows that given connectors…

28 Jun 2022 08:30 AM IST

Photo Realistic Rendering

REPORT OF AMERICAN CHOPPER: INTRODUCTION: The chopper symbolizes both power and style.The characteristic features of choppers are long front forks often coupled with an increased rake angle,large rear wheels and relatively slim front wheels,streched frames. AIM & OBJECTIVE: To learn the solidworks interface and simultaneously…

02 Jul 2022 10:18 PM IST

Week 8 - Challenge 1 - Base Bracket Design

AIM: Create the Base Bracket Plastic component through the given Class-A surface. Class-A Surface should be created meeting the requirements of the draft angle and at the end perform the Draft analysis on the model. OBJECTIVE: To crate a tooling axis for the plastic component To create a base bracket…

26 Jul 2022 07:45 AM IST

Week 8 - Challenge 2 - Switch Bezel Design

AIM: Create the Switch Bezel Plastic component through the given Class-A surface. Class-A Surface should be created meeting the requirements of the draft angle and at the end perform the Draft analysis on the model. OBJECTIVE: To crate a tooling axis for the plastic component To create a Switch Bezel of plastic component…

26 Jul 2022 08:20 PM IST

Week 8 - Challenge 3 - Coin Holder Design

AIM: Create the Coin Holder Plastic component through the given Class-A surface. Class-A Surface should be created meeting the requirements of the draft angle and at the end perform the Draft analysis on the model. OBJECTIVE: To crate a tooling axis for the plastic component To create…

27 Jul 2022 10:31 PM IST

Week 8 - Challenge 4 - Bumper

AIM: Create the Bumper Plastic component through the given Class-A surface. Class-A Surface should be created meeting the requirements of the draft angle and at the end perform the Draft analysis on the model. OBJECTIVE: To crate a tooling axis for the plastic component To create a Bumper…

28 Jul 2022 10:38 PM IST

Week 9 - Attachment Feature Creation (Ribs & Screw Boss) - Challenge 1

AIM: Create the Drill Handle Plastic component through the given Class-A surface. Class-A Surface should be created meeting the requirements of the draft angle and at the end perform the Draft analysis on the model. OBJECTIVE: Create the rib for the Drill Handle considering the design rules Create the Screw boss for…

01 Aug 2022 09:16 PM IST

Week 9 - Attachment Feature Creation - Challenge 2

AIM:Create the Dog House for the Door Trim considering the design rules OBJECTIVE:Create the Dog House for the Door Trim considering the design rules To perform the draft analysis over the plastic component.IMPORTING THE MODEL Open the downloaded IGES file make it has class A surface by jioning all…

03 Aug 2022 09:49 AM IST

Week 9 - Project 1 - Door Trim Lower with Engineering Features

AIM: Create the Door Trim Plastic component through the given Class-A surface. Class-A Surface should be created meeting the requirements of the draft angle and at the end perform the Draft analysis on the model. Then Create the Heat Stakes and the locators considering the design rules OBJECTIVE:…

03 Aug 2022 09:41 PM IST

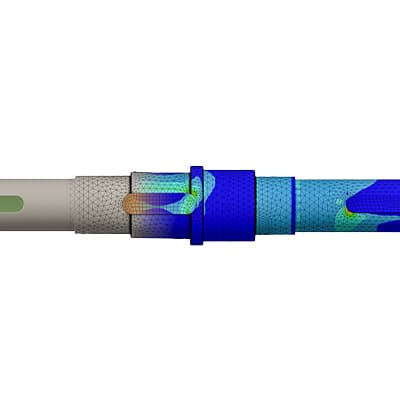

Week 10- Assembly Workbench

Aim: To create quick return mechanism and CV joint parts in part workbench and assemble them , After creating the assembly make use of the drafting tools to create a 2D drawing Procedure: Create the sketches of the given component in sketcher work bench with help of tools like line ,circle , rectangle…

04 Aug 2022 06:20 PM IST

Week 9 - Project - A pillar Design with Master Section

AIM: Create A pillar Design with Master Section OBJECTIVE: Craetion of proper tooling direction following themastrer section to create the part that meet the requirements Draft analysis check to make sure that the class A surface is meeting the draft required along the tooling direction Creation of Dog house,…

06 Aug 2022 10:54 PM IST

Week 11 - Final project

AIM:Development of a Door Trim panelOBJECTIVE:To crate a tooling axis for the plastic componentTo create a Door Trim panel from given Class A surface.To perform the draft analysis over the plastic component.Create the Heat Stakes and the Push pin with Dog house considering the design rules INTRODUCTION: …

14 Aug 2022 07:36 PM IST

Week 8 - Challenge 6 - Core & Cavity Design

AIM: Create the Core and cavity blocks for the switch bezel OBJECTIVE: To crate a tooling axis for the plastic component To create a Switch Bezel of plastic component from given Class A surface. To perform the draft analysis over the plastic component. Creation of Core Cavity Blocks for the switch bezel PROCEDURE: Generating…

15 Aug 2022 06:40 PM IST

Benchmarking

OBJECTIVE : Picking up a car as per customer's requirement with the help of Benchmarking. Benchmarking : Benchmarking in the automobile industry involves a structured comparison between similar products, services on some dimensions of Performance. Benchmarking is a huge process that involves many days that must be tracked…

18 Aug 2022 09:34 PM IST

Underbody Coating

AIM: To Study About Under-Body Coating, its types in detail and its pros and cons. Introduction: What is underbody coating for automobiles? Underbody coating is usually a dense cladding (often based on rubber) applied uniformly to the undercarriage of the automobile. It is normally sprayed or painted on when the car…

19 Aug 2022 09:18 AM IST

Hood design-Week 2

Aim: To Design Hood outer panel, inner panel and the necessary reinforcements by following the Master section with the design parameter Introduction: Hood is the main component of a car at the front portion. It is used to decorate the car and add a luxurious look. The shape of the Hood is made aerodynamic in order to minimize…

28 Aug 2022 06:36 PM IST

Fender Design - Wheel Arch Challenge

AIM: To calculate the wheel arc area and decide whether the car will pass the European standards or not. FENDER: Fender is the US English term for the part of an automobile (vehicle body) that frames a wheel well (the fender underside). Its primary purpose is to prevent sand, mud, rocks, liquids, and other…

29 Aug 2022 11:16 AM IST

Section Modulus calculation and optimization

Aim: To find the section modulus of the hood and optimization to improve the overall section modulus. Objective: Use the section from your Hood design and calculate the section modulus using the formula S= I/y. Section Modulus: The section modulus (S) is geometry property of the cross section used for designing beams and…

29 Aug 2022 06:37 PM IST

Fender Design Challenge

OBJECTIVE : The main objective of this project is to design a fender using a new age design software - NX - CAD FEATURES/TOOL USED: SKETCH OFFSET IN FACE CURVE ON SURFACE BRIDGE CURVE EMBOSS TRIM SHEET LAW EXTENSION FACE BLEND EDGE BLEND DART THICKEN INTRODUCTION : Design of any product starts from an requirement…

31 Aug 2022 07:44 PM IST

Roof Design

ROOF DESIGN OBJECTIVE : The objective of this project is to design car roof with essential flanges and reinforcements like ditch area , front roof rail , bow roofs, central roof rail and rear roof rail for the the given styling surface Perform a curvature study on the roof and perform the calculations…

13 Sep 2022 07:16 PM IST

Design of backdoor

Objective: To Develop Back door of the Car by using given styling surface & provide necessary embosses and reinforcement to the back door Software Used: NX Cad INTRODUCTION: The Back Door of a car is the rearmost part of the vehicle which gives access to the trunk space…

23 Sep 2022 09:07 PM IST

Week 7 Challenge

AIM: Create the core-cavity, slider blocks for the given component PROCEDURE STEP-1: Deciding the tooling direction Selected the tooling direction which leads to minimum udercuts done draft analysis to check adequate drafts in the model core cavity STEP-2: Scaling the model Increased the model size by 0.6% to account shrinkage…

16 Aug 2023 02:49 PM IST

Project 1

OBJECTIVE: Creation of Mould for a table fan outer casing using SolidWorks. INTRODUCTION: The injection moulding process involves heating & injecting plastic material under pressure into a closed metal mould tool. The molten plastic cools & hardens into the shape inside the mould tool, which then opens to allow the mouldings…

18 Sep 2023 04:29 PM IST

Week 9 Challenge

AIM: Create the core-cavity, slider blocks & Undercuts for the given component PROCEDURE STEP-1: Deciding the tooling direction Selected the tooling direction which leads to minimum udercuts done draft analysis to check adequate drafts in the model core cavity STEP-2: Scaling the model Increased the model size by 0.6%…

16 Oct 2023 03:23 PM IST

Week 12 Challenge

Aim creation of a proper ejection system with ejector pins and plates, runner and gate system, air vents and cooling channels for the mold. Ejection system The ejection system in molding refers to the mechanism used to remove a finished plastic part from the mold cavity. The ejection system consists of ejector pins,…

12 Dec 2023 02:59 PM IST

Project 2

OBJECTIVE:Creation of Mould for a cpu fan bezel using SolidWorks.INTRODUCTION: The injection moulding process involves heating & injecting plastic material under pressure into a closed metal mould tool. The molten plastic cools & hardens into the shape inside the mould tool, which then opens…

12 Feb 2024 01:50 PM IST

Week 2:- BiW Fixture Basics Challenge

1.What is the process of project execution activity? Project activities are those basically are being processed or being practiced in general project of BIW begins. Project activities are task from start to end of project. There are various steps involved in project. Below fig. show flow chart of project activities. 1.…

25 Feb 2024 03:31 PM IST

Week 3:- BiW Fixture Design Methodologies Challenges

1. What is Design Methodology? Design Methodology is a sequence of steps that we have to follow while doing design. The above image is of the design methodology and steps involve in it. 1.Purchase Order: We start designing after the customer gives us a purchase order. So, basically, it is an indication…

11 Mar 2024 05:10 PM IST

5 Course Certificates

Automotive Sheet Metal Design using Siemens NX CAD / CATIA V5

Academic Qualification

B.E

CIT tumkur

01 Aug 2015 - 27 Aug 2020

12th

Vidyanidhi independent PU College

02 Jun 2014 - 01 Apr 2015

10th

Shree Siddaganga Math

01 Jun 2012 - 01 Apr 2013

Here are the courses that I have enrolled

Similar Profiles

Ladder of success cannot be climbed with hands in pocket.

The Future in Motion

Give more than what you get you will get more than what you gave

Avid learner