Tarun kumar

Skills Acquired at Skill-Lync :

- HYPER-MESH

- STRUCTURAL-MESHING

- SHEET-METAL-MESHING

- ANSA

- MATLAB-BASICS

- FEA

- RADIOSS

- CRASH-WORTHINESS

27 Projects

Week 4- Challenge

1.Ans. Objective:To mesh the given component with the size of 5mm and to create 1D elements of the component with given cross section and Degrees of freedom(DOF). Procedure: Firstly import the model from the system files. The model we imported will be in wire frame model.So, convert it into shaded view. Then Create a…

27 Jan 2021 09:27 AM IST

Week 6-Meshing of Hood Challenge

Meshing of Hood challenge: Objective: To mesh the hood by extracting mid-surface for each components and assign them the thickness from the mentioned quality criteria. CAD Model Image: Procedure: Firstly import the model from the system files. Then delete the…

15 Jul 2021 08:42 AM IST

Week 8-3D Tetra Meshing Challenge

Housing Model: Objective: To create a tetramesh for housing component by using Tetramesh generation method by converting the model from 2D to 3D with mentioned criteria. CAD Model Image: Procedure: Firstly import the Geometry(IGES) file from the System files.…

06 Jan 2022 06:10 PM IST

Week 9-Creation of 1D Connectors Challenge

Creation of 1D connectors challenge: Objective: To generate the 2D mesh for the given geometry and also to create connectors to attach the various parts of the model as mentioned below. Target Element size - 5 Units S.N Quality Criteria Value …

21 Jan 2022 08:09 AM IST

Week 12:Project-1-Meshing of Door Inner Panel Challenge

Meshing Of Door Inner panel Challenge: Objective: To mesh the given Door's inner panel with the mentioned quality criteria and assigning them the thickness. Target Element Length = 4 Units S.N Quality Criteria Value 1 Aspect Ratio 5 2 Skewness…

22 Feb 2022 06:32 PM IST

Week 12:Project 2-Meshing of Rear Wheel Holder challenge

Meshing of Rear wheel holder challenge: Objective: To mesh the rear wheel holder with the mentioned quality criteria and assigning them the thickness. CAD Model Image: Procedure: Firstly import the model from the system files. Before extracting the mid…

07 Mar 2022 05:09 PM IST

Week 3 - 2D meshing for sheet metal

Week 3: 2D Meshing for Sheet Metal: Aim: To extract the mid surface for the given hood model after cleaning up all the geometrical errors and then mesh the model with the given element quality criteria. Objective: For the given Hood model, Take the mid surface for all the components after…

25 Apr 2022 05:35 PM IST

Week - 4 - 2D meshing for Plastic components

2D Meshing for Plastic Components: Aim: To extract the mid surface for the given plastic bottle cap model and assigning the thickness and mesh them with the given or mentioned quality parameters. Objective: For the given Plastic Bottle Cap model, check for the geometrical errors and take…

26 May 2022 05:55 PM IST

Tool Test 1

Tool Test-1 Model -1: Time taken for the model 8 Hours. There are some failed elements in the model near Triple cons. Model-2: Time taken for the model 3hours 45 min.

08 Jun 2022 07:50 AM IST

Week- 5 - Solid meshing

Solid Meshing: Aim: For the given rear view component we need to check for geometrical errors and mesh them with 2d element quality criteria and after that we need to use tetra elements to mesh the volumes defined for the model with the mentioned quality criteria. Objective: For the given…

12 Jun 2022 12:31 PM IST

Tool Test-2

Tool test-2: Time taken for the model- 7 hours 30min.

14 Jun 2022 03:38 PM IST

Week 6 - Creating connection for Rear door

Creating Connection for Rear Door: Aim: To perform suitable connections on the rear door model by creating and applying different PID'S for the component. CAD Model Image: Procedure: Firstly import the model from the system files. Before creating connections for the model firstly we need to assign…

21 Jun 2022 10:55 AM IST

Week - 8 - Morphing

Morphing: Aim: To morph the given model as per the video shown in Model-1. Procedure: Firstly import the CAD model from the syatem files into ANSA. The imported model is as follows. Then after 'Topo' the whole model using topo option in Faces. Goto>Topo Module>Faces>Topo. The…

03 Jul 2022 12:07 PM IST

Week 1 Stress Concentration on a Plate with hole

Week 1: Sress Concentration on a plate with Hole: Aim:To compare the deformation and maximum stress developed on a structural steel for both the cases (1&2) from analysis stand point and manufacturing stand point. Objective: Case :1 Design a plate with a hole model similar to what we worked in the class, but with increased…

11 Jul 2022 04:44 PM IST

Week 1 Spur Gear Challenge

Spur Gear Challenge: Aim: To carry out a static structural analysis to find equivalent stress,total deformation and stress intensity of the three materials which are 1)Cast Iron 2)Cast Steel 3)Cast Bronze Objective: Objective 1: Case 1: Using Cast Iron(ductile) as a material, carry out a static…

22 Jul 2022 08:39 PM IST

Week 2 Bevel Gear Challenge

Bevel Gear Challenge: Aim: To understand the concept of grid dependency test and perform the test for the bevel gear simulation for the mesh sizes of 6mm,5mm and 4mm.And solve for equivalent stress,Equivalent elastic strain and total deformation. Objective: 1)Write a few words on…

28 Jul 2022 07:45 PM IST

Week 2 Railwheel and Track

Railwheel and Track: Aim: To perform a static structural analysis on the railwheel and track setup and gain results for total deformation,equivalent stress,life and user defined results of given loads. Objective: Perform a static structural analysis on the Railwheel and Track setup and Case 1: Multiply the bearing…

02 Aug 2022 08:58 PM IST

Week 3 Verification of Weld Joints

Verification of Weld Joints: Aim: To simulate three different types of welding using different weld materials as stainless steel,Aluminium alloy,Bronze and copper for the given welded joint. Objective: Simulate three different types of welding using three different weld materials Weld…

04 Aug 2022 08:51 PM IST

Week 3 Sheet metal Bending challenge

Bending of Sheet metal: Aim: To perform sheet metal bending using three different materials as Aluminium alloy,Copper alloy NL and magnesium alloy NL as observed in the below cases. Objective: sheet metal bending is to be performed for 3 different materials mentioned below. Variation of certain settings is also to be performed…

17 Aug 2022 07:45 PM IST

Week 4- Rolling operation

Rolling Operation: Aim: To simulate the rolling operation on a work piece made of copper with mentioned dimensions and steps for knowing Equiavalent stress,Equivalent plastic strain and Directional deformation. Objective: For this challenge, you will have to simulate the rolling operation…

23 Aug 2022 07:12 PM IST

Week 4 -Wire Bending Challenge

Wire Bending Challenge: Aim: To perform an analysis to simulate the bending of wire using the materials as copper alloy(NL),Aluminium alloy(NL) and Magnesium alloy(NL) for the wire to find the equivalent stress and equivalent strain. Objective: for this challenge, you will have to perform…

12 Sep 2022 06:10 PM IST

Week 5 Sphere pressing on a plate

Sphere pressing on a plate: Aim: To perform the analysis to simulate a sphere pressing a plate using structural steel for the sphere and non-linear structural steel for the plate as the materials and to find deformation on the plate,along equiavalent stress and strain on both sphere and…

14 Sep 2022 02:13 PM IST

Week 7-Long Piston With Cam

Long Piston with CAM: Aim: To perform transient analysis on a piston and cam mechanism that has been provided. Objective: For this challenge, you will have to perform a transient analysis on a piston and cam mechanism model that has been provided to you. You need to run the analysis with Frictionless contact,…

28 Sep 2022 04:28 PM IST

Week 9 Machining with Planer Challenge

Machining with planar Challenge: Aim:To perform explicit dynamics simulation for machining with the planar to find equivalent stress,deformation. Objective: You will have to perform an explicit dynamics simulation to find out the Equivalent Stress, Total Deformation and also insert a User defined result to calculate the…

17 Oct 2022 05:33 PM IST

Week 9 Tension and Torsion test challenge

Tension Test and Torsion test challenge: Aim: To perform the tension and torsion test on the given model to find out the total deformation,Equivalent stress and Temperature. Objective: For this challenge, you will have to perform the tension and torsion test on the specimen provided below the video corresponding to the…

20 Oct 2022 12:50 PM IST

Week 10 Bullet penetrating a Bucket Challenge

Bullet Penetrating Through Bucket: Aim: To simulate the bullet penetrating into a bucket using three different non-linear materials for the bucket. Objective: For this challenge, you will have to simulate a bullet penetrating into a bucket. You will need to use 3 different non linear materials for the bucket and analyse…

27 Oct 2022 03:01 PM IST

Week 11 Car Crash simulation

Car Crash Simulation: Aim: To perform a parametric study using 3 different values of thickness for carbody . Objective: For this challenge, you will have to perform a parametric study using 3 different values of thickness for the car body. You need to apply the same conditions as mentioned in the video that corresponds…

03 Nov 2022 01:50 PM IST

4 Course Certificates

HyperMesh for FEA Plastic and Sheet Metal Applications

Introduction to Structural Analysis using ANSYS Workbench

Academic Qualification

B.Tech

Avanthi Institute Of Engineering & Technology

01 Jun 2012 - 31 May 2016

12th

Narayana Junior College

01 Jun 2010 - 31 May 2012

10th

Gautami talent high school

01 Jun 2009 - 30 Apr 2010

Here are the courses that I have enrolled

Similar Profiles

Ladder of success cannot be climbed with hands in pocket.

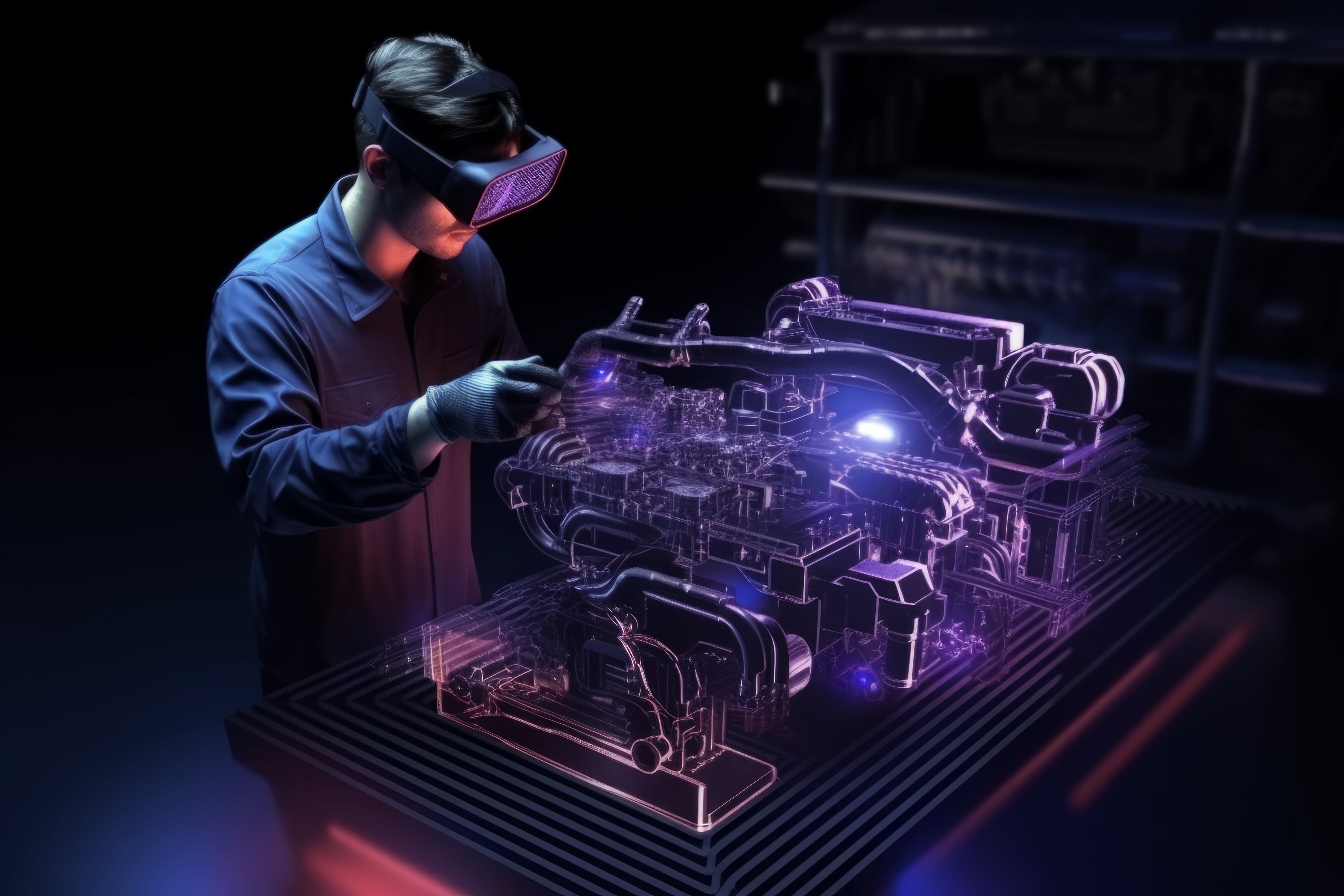

The Future in Motion

Give more than what you get you will get more than what you gave

Avid learner