Azeezur Rahman M

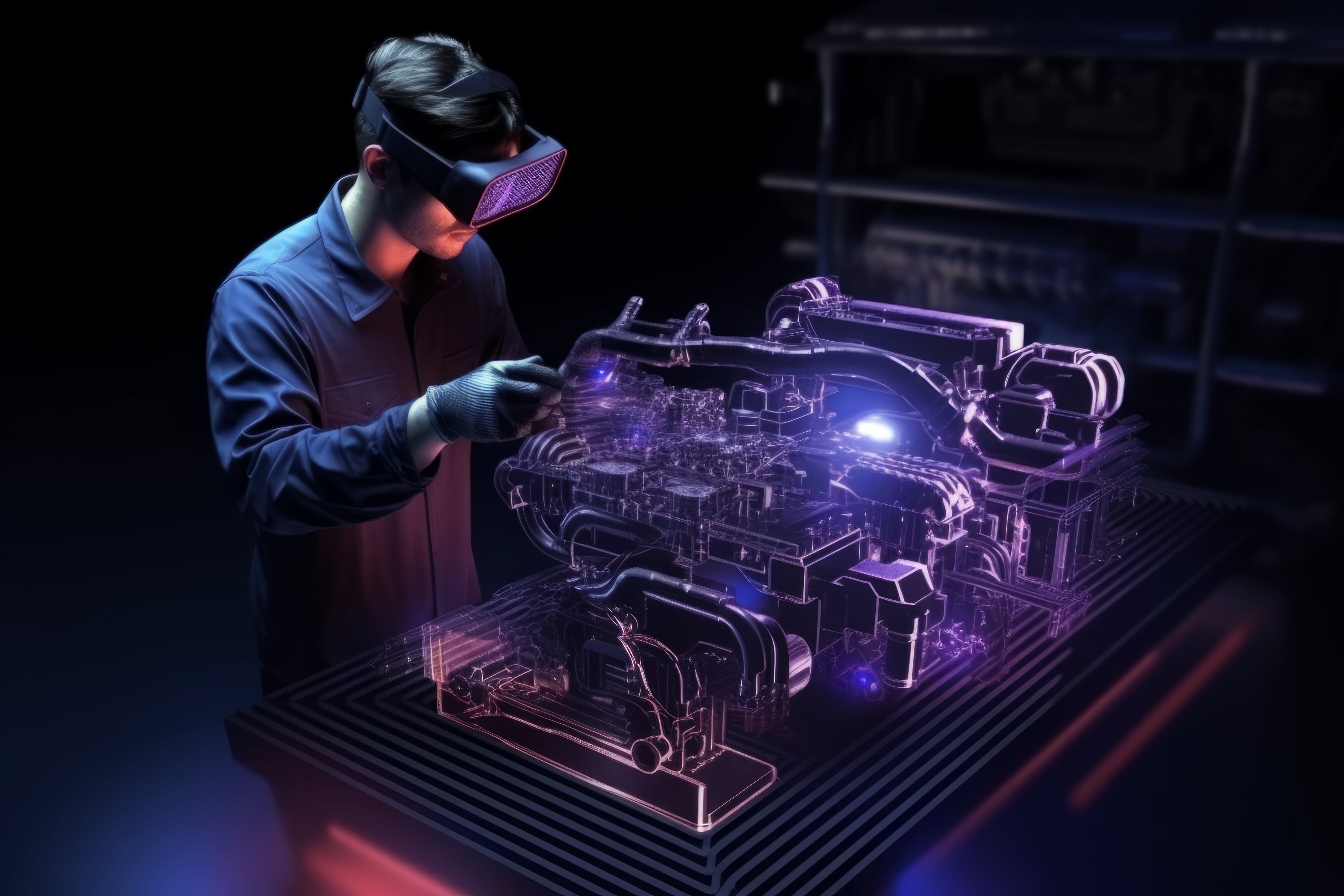

CAE Engineer | Expertise in Preprocessing - ANSA & Hypermesh | Skilled in meshing of plastic trims & BIW parts | Excelled in tetra modelling | Pursuing CAE master’s

Skills Acquired at Skill-Lync :

- STRUCTURAL-MESHING

- ANSA

- HYPER-MESH

- SHEET-METAL-MESHING

- NX-CAD

- SHEET-METAL-DESIGN

- BIW-DESIGN

- FEA

Introduction

27 Projects

BASICS OF BIW FIXTURES - Part 2

Question NO.3 - What is Fusion welding & types of fusion welding with its application in automotive sectors ? Answer: FUSION WELDING: In fusion welding,the metal at the joint is heated to a molten state and then it is allowed allowed to solidify. Pressure is not applied during the welding process and hence it…

13 Apr 2020 04:55 AM IST

BIW FIXTURES PRE - DESIGN PROCESS ( Design Methodology & Structuring a design tree )

Question No.1 - What is Design methodologies ? Answer: DESIGN METHODOLOGIES: Design methodologies is nothing but the steps followed during the concept designing stages of fixture design. The various stages of design methodologies are, Purchase order. Inputs from customer. Percentage of completion criteria. Design…

13 Mar 2020 08:46 AM IST

BASICS OF BIW FIXTURES - Part 3

Question No.4 - What is resistance welding & its application in automotive sector? Answer: ELECTRIC RESISTANCE WELDING: Resistance welding is a welding technique widely used in manufacturing industry for joining metal sheets & components. This type of welding is very much used in BIW assemblies most…

13 Apr 2020 04:56 AM IST

BIW fixtures - Pin unit design (fixed pin & retractable pin units)

OBJECTIVE: To design 2 different types of fixed pin unit with different pins, riser, blade & block and 2 different types of retractable pin unit with different pins, riser, blade, cylinder & block. SOFTWARE USED: CATIA V5 COLOUR CODES IN BIW FIXTURE: …

13 Mar 2020 08:47 AM IST

BIW fixture - Design of power clamp unit

OBJECTIVE: To design 3 different types of power clamp unit with different riser, blade and clamp arm & to design 2 Different types of rest Unit for the given Car Panel. ABSTRACT: In this project I have designed a different types of power clamp unit by validating a power clamp cylinder and by considering a clamping…

23 Apr 2020 07:22 AM IST

DIFFERENT TYPES OF UNITS IN FIXTURE - Theory

Question No.11 - What are units ? mention 5 types of units. Answer: UNITS: In general , units is a device that has a specified function, especially one forming part of a complex mechanism. A welding fixtures is a assembly of different types of units. As name refers, the different units will be only seen in the unitized…

16 Mar 2020 01:26 AM IST

INTRODUCTION TO BIW FIXTURES - Part 1

Question No.1 - What is BIW & define its parts ? Answer : BIW: BIW - Body In White. BIW refers to the welded sheet metal components which form the vehicles structure to which the other components (like engine, chasis, exterior & interior trims) will be married or assembled. The stage in automotive design or automobile…

16 Mar 2020 01:25 AM IST

Performed shell mesh for a CAR HOOD - using ANSA

AIM: To check for the geometrical errors and mesh with the given element Quality criteria. After meshing the component the thickness has to be assigned for the given component. GIVEN DATA: The given data are the inputs to work. Here the given data are, CAD model. Quality criteria. CAD MODEL: Here the given…

04 Nov 2020 12:08 PM IST

Performed shell mesh for a PLASTIC BOTTLE CAP - using ANSA

AIM: To check for the geometrical errors and mesh with the given element Quality criteria. After meshing the component the thickness has to be assigned for the given component. NOTE: In this challenge, there will be some off elements found in the chamfer region which cant be removed. It is acceptable as it is been found…

04 Nov 2020 12:08 PM IST

TERTA MODELLING FOR A REAR VIEW MIRROR OF PASSENGER CAR - using ANSA

AIM : To check for the geometrical errors and mesh with the given element Quality criteria. And to use tetra elements to model the component and there should not any kinks and dips on the surface of the component. GIVEN DATA : The given data are the inputs to work. Here the given data are, CAD model. Quality criteria.…

13 Nov 2020 01:16 PM IST

TETRA MODELLING FOR ENGINE INTAKE MANIFOLD using ANSA - Tool test 2

TOOL TEST - 2: DURATION: ESTIMATED OR GIVEN TIME : 5 Hrs. TIME TAKEN TO COMPLETE THE TEST : 5 Hrs. 30 mins. Figure 1. Duration …

13 Nov 2020 01:16 PM IST

CASE STUDY OF DIFFERENT METHODS OF MID SURFACE EXTRACTION & MESHING FOR A GIVEN SHEET PANEL

AIM: To compare the results on different mesh generation & mid surface extraction method for a given sheet metal component. Also to give a detailed report stating that which method gives best mesh flow & which would be the best way. GIVEN DATA: Cad model Quality Criteria …

15 Dec 2020 09:28 AM IST

Basic Morphing Techniques using ANSA

AIM To practice all the Morphing techniques that were shown in the video for the given component & to write a report on Morphing and its use cases in various industries. MORPHING Morphing is a design change terminology or used to change the design or shape of any component without any numerical inputs. We can try morphing…

21 Dec 2020 06:44 AM IST

DEPLOYED NECESSARY CONNECTIONS FOR A FE MODEL - REAR DOOR OF A PASSENGER VEHICLE using ANSA

AIM To deploy necessary connections for the given rear door FE model. GIVEN DATA FE model of rear door Figure 1 - Given…

24 Dec 2020 08:03 AM IST

Project 1 - 2D meshing on the instrumental Panel using ANSA

AIM: To perform FE modelling of an Automotive IP trim component by considering the given element Quality criteria. NOTE: In this challenge, there will be some off elements found in the chamfer region which cant be removed. It is acceptable as it is been found due to the presence of triple cons on the chamfered surface.…

16 Apr 2021 04:27 PM IST

Project - 2 - FE Modelling of a Rear suspension Assembly using ANSA

AIM : To Perform FE Modelling of an Automotive rear suspension assembly. GIVEN DATA : The given data are the inputs to work. Here the given data are, CAD model. Quality criteria. CAD MODEL: Here the given cad model is Rear suspension assembly of an automobile. …

16 Apr 2021 04:28 PM IST

Week 4-1D Element Creation Challenge using HYPERMESH

AIM: To Mesh the Given component with the Size of 5 Units & to Create 1D elements on the following component with given cross-section and DOF. GIVEN DATA: a. Rod element:- Translational DOF should be Constrained with RBE2 link Cross-Section: BOX- Dimension a= 12 mm …

16 Apr 2021 04:28 PM IST

Week 6-Meshing of Hood using HYPERMESH

AIM: To mesh the given hood assembly of a passenger vehicle meeting the given quality criteria along with good mesh flow. Figure 1. Hood Assembly GIVEN DATA: The given data are the inputs to work. Here the given data are, CAD model. Quality…

16 Apr 2021 04:27 PM IST

Week 8-3D Tetra Meshing Challenge

MODEL 1 - 2D to 3D Conversion method. AIM: To Create a Teramesh for Housing component with the following quality criteria by following TetraMesh Generation Method: 2D to 3D Conversion. GIVEN DATA: The given data are the inputs to work. Here the given data are, CAD model. Quality criteria. 1.Cad model: …

03 Jun 2021 07:25 AM IST

Week 9-Creation of 1D Connectors Challenge

AIM To mesh the given geometry by achieving the given quality criteria and to deploy necessary connections as given. GIVEN DATA Here the given data are, Cad model. Quality criteria. Connection details. CAD MODEL - Midsurface: …

09 Jun 2021 08:06 AM IST

Extracted mid surface & Performed shell mesh manually for a tailgate of a passenger vehicle using HYPERMESH

AIM: To mesh the given Tail gate of a passenger vehicle meeting the given quality criteria along with good mesh flow. Figure 1. Tail gate GIVEN DATA: The given data are the inputs…

17 Jul 2021 07:15 AM IST

Performed Batch meshing for a 'car hood assembly' using HYPERMESH

AIM To Perform Batch-meshing on the given components (Fender & Hood assembly - BIW component) with the given criteria and assign the non-linear material property Steel for Radioss profile to them. GIVEN DATA CAD Model. Quality Criteria. Parametric file. 1. CAD MODEL: Here the given cad model are BIW Components,…

17 Jul 2021 07:21 AM IST

Basic Morphing Techniques using HYPERMESH

AIM To practice all the Morphing techniques that were shown in the video for the given component & to write a report on Morphing and its use cases in various industries. Refer to the following images for Morphing GIVEN DATA …

17 Jul 2021 09:55 AM IST

Week 12:Project-1-Meshing of Door Inner Panel Challenge

AIM: To perform FE modelling of an Automotive Side Door inner panel trim component by considering the given element Quality criteria. Figure 1 - Automotive Side door inner panel NOTE: In this challenge, there will be some off elements found in the chamfer region which cant be removed. It is acceptable…

28 Jul 2021 01:44 PM IST

Week 12:Project 2-Meshing of Rear Wheel Holder challenge

AIM: To perform FE modelling of an Automotive Spare wheel holder - Stamped sheet metal component by considering the given element Quality criteria. Figure 1 - Automotive Spare wheel holder panel GIVEN DATA: The given data are the inputs to work. Here the given data are, CAD model. Quality…

31 Jul 2021 08:45 AM IST

2 Course Certificates

HyperMesh for FEA Plastic and Sheet Metal Applications

16 Workshop Certificates

What makes a good BMS? Module relevance & its role as safety manager in new Electric Vehicle technologies

What makes a good BMS? Module relevance & its role as safety manager in new Electric Vehicle technologies

What makes a good BMS? Module relevance & its role as safety manager in new Electric Vehicle technologies

What makes a good BMS? Module relevance & its role as safety manager EV Tech

Academic Qualification

B.Tech

B. S. Abdur Rahman Crescent Institute Of Science And Technology

15 Jun 2014 - 15 Mar 2018

12th

Velammal Matriculation School Mogappair (Main)

01 Jun 2013 - 01 Mar 2014

10th

Shri Krishnaswamy Matriculation Higher Secondary School

01 Jun 2011 - 02 Apr 2012

Here are the courses that I have enrolled

Similar Profiles

Ladder of success cannot be climbed with hands in pocket.

The Future in Motion

Give more than what you get you will get more than what you gave

Avid learner