Rajeev Reddy

Make it happen

Skills Acquired at Skill-Lync :

- NX-CAD

- SHEET-METAL-DESIGN

- BIW-DESIGN

- HYPER-MESH

- STRUCTURAL-MESHING

- SHEET-METAL-MESHING

- FEA

- RADIOSS

Introduction

23 Projects

Week 8 - Challenge 1 - Draft Analysis on a Fan Cover

DRAFT ANALYSIS OF FAN COVER

02 Feb 2021 06:01 AM IST

Week 8 - Challenge 2 - Base Bracket Design

BASE BRACKET CATPART

02 Feb 2021 07:12 AM IST

Week 8 - Challenge 3 - Switch Bezel Design

AIM: To add thickness to the given class A surface of Switch Bazel and Base Bracket to create a closed body. SWITCH BAZEL BASE BRACKET

25 Mar 2021 06:59 AM IST

Week 8 - Challenge 4 - Coin Holder Design

REPORT ON DRAFT ANALYSIS: Dear team, As the below images shows, I am unable to get a proper draft analysis to the side wall of the body beacuse the side walls of the coin holder is not given with a draft angle. In the image the angle between the side walls and the base is 90 degrees which indicates these sides are not…

08 Feb 2021 12:55 PM IST

Week 8 - Challenge 5 - Core & Cavity Design

AIM: To design a core and cavity for the closed body of switch bazel. PARTING LINE AND PARTING SURFACE DRAFT ANALYSIS The green colour in the below images indicates that the walls are given with the 3 degree draft angle with respect to tooling axis CORE AND CAVITY BOX IN DIFFERENT ORIENTATION …

25 Mar 2021 06:55 AM IST

Week 9 - Attachment Feature Creation - Challenge 1

COIN HOLDER WITH RIBS

10 Feb 2021 10:34 AM IST

Week 9 - Attachment Feature Creation - Challenge 2

AIM : To create an attachment features to the coin holder COIN HOLDER WITH SCREW BOSS AND DOGHOUSE

25 Mar 2021 06:56 AM IST

Door Arm Rest Week 8 Challenge

DRAFT ANALYSIS REPORT ON DOOR ARM REST Dear team, As per the below images, I am able to get a draft angle every where on the body using main tooling axis and side core tooling axis except the left corner portion of the body. Since it has a bend shape I am unable to get draft angle at that position. So I request…

13 Feb 2021 05:24 AM IST

Week 9 - Project 1 - Door Applique Design with Engineering Features

AIM: To add thickness to the class A surface and to design all the engineering features required to make an assembly. DRAFT ANALYSIS REPORT To create a tooling axis, I took a reference of A surface and created a line which meets the draft requirements. In the below images the green colour shows that the body is meeting…

25 Mar 2021 06:53 AM IST

Week 11 - Final project

AIM : To create a closed solid body of Side Door plastic trim including with all the Engineering features and adding thickness to the given class A surface using CATIA V5 tool. INTRODUCTION: Side Door Plastic Trim : An interior component attached to the inner side of the door. This product improves the…

23 Mar 2021 07:40 AM IST

Benchmarking

BENCHMARK Benchmarking is the practice of comparing business process and performance metrics to industry bests and best practices from other companies. Dimensions typically measured are quality, time and cost. Benchmarking is used to measure performance using a specific indicator (cost per unit…

25 Mar 2021 05:05 AM IST

Underbody Coating

UNDERBODY COATING What is underbody coating? Underbody coating provides long term protection from corrosion to car’s underbody. It also protects parts like internal body panels, frame rails and other inner cavities that are not physically accessible but are prone to corrosion. This is especially important for…

06 Apr 2021 04:42 AM IST

Hood design-Week 2

AIM: To design hood outer panel, inner panel, necessary reinforcements and the embosses by considering the master section and design parameters. INTRODUCTION: In British terminology, hood refers to a fabric cover over the passenger compartment of the car (known as the 'roof' or 'top' in the US). In many motor…

30 Mar 2021 11:27 AM IST

Section Modulus calculation and optimization

AIM: To calculate and compare the section modulus of the hood design and to conclude which one has a more strength. INTRODUCTION OF SECTION MODULUS: Section modulus is a geometric property for a given cross-section used in the design of beams or flexural members. Other geometric properties used in design include area for…

30 Mar 2021 05:52 AM IST

Fender Design Challenge

DESIGN OF CAR FENDER AND MOUNTING STRUCTURES FENDER: Fender is the American english term for the part of an automobile, motorcycle or other vehicle body that frames a wheel well (the fender underside). Its primary purpose is to prevent sand, mud, rocks, liquids, and other road spray from being thrown into the air…

06 Apr 2021 04:43 AM IST

Roof challenge

AIM: To Design a Car Roof and to do the curvature study to resist Heat distortion and snow load condition of the same. INTRODUCTION : An automobile roof or car top is the portion of an automobile that sits above the passenger compartment, protecting the vehicle occupants from sun, wind, rain,…

20 Jul 2021 06:12 AM IST

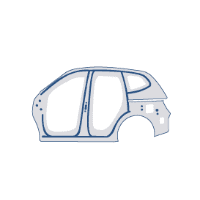

Design of backdoor

Aim: To design a Back Door by using given styling surface by providing all the necessary rienforcement and embosses and by considering the appropriate design parameters. INTROUCTION : A door is a hinged part which is used for the entry and exit of the vehicles . Back door are the one of the type doors of the vehicle which…

22 Sep 2021 12:17 PM IST

Week 4-1D Element Creation Challenge

AIM: To study and create 1D element on the given component. OBJECTIVE: To Mesh the Given component with the Size of 5 Units. Create 1D elements on the following component with given cross-section and DOF. a. Rod element:- Translational DOF should be Constrained with RBE2 link Cross-Section: BOX- Dimension…

30 Sep 2021 10:22 AM IST

Week 6-Meshing of Hood Challenge

AIM: To Meshing of Hood which is provided in the challenge. OBJECTIVE: To set up the quality criteria as given and Mesh the components of Hood. Element size and Quality Criteria given: Target Element Length = 5 Units S.N Quality Criteria Value 1 Aspect Ratio 5 2 Skewness 45 3…

02 Nov 2021 01:28 PM IST

Week 8-3D Tetra Meshing Challenge

AIM: To Create 3D tetra meshing on the given component. OBJECTIVE: To Create a Teramesh for Housing component with the following quality criteria. TetraMesh Generation Method: 2D to 3D Conversion Elements sizes: Min- 2 Units, Target- 5 Units, Max- 7 Units Tet collapse: 0.15 For the given model, Create a 3D Tetramesh with…

11 Nov 2021 01:25 PM IST

Week 9-Creation of 1D Connectors Challenge

AIM: To create 1D connectors to connect between different components. OBJECTIVE: To Create connector and Attach the various parts of the given model. 1. Right_Rail_2 & Front_truss_1:- Seam-Quad(angled+capped+L) 2. Left_Rail_2 & Front_truss_1:- Quad elements 3. Front_truss_2, Front_truss_1…

12 Nov 2021 06:40 AM IST

Week 12:Project-1-Meshing of Door Inner Panel Challenge

AIM: To Mesh the door inner panel (plastic component). OBJECTIVE: To mesh the given component with the given criteria. Target Element Length = 4 Units S.N Quality Criteria Value 1 Aspect Ratio 5 2 Skewness 45 3 Warping 15 4 Taper 0.5 5 Min. Length 2 Units 6 Max. Length 6 Units 7 Min angle Quad 45 8 Max angle Quad…

27 Nov 2021 02:33 AM IST

Week 12:Project 2-Meshing of Rear Wheel Holder challenge

AIM: To mesh the Rear wheel holder. OBJECTIVE: To mesh the given component with the given quality criteria. Target Element Length = 5 Units S.N Quality Criteria Value 1 Aspect Ratio 5 2 Skewness 45 3 Warping 15 4 Taper 0.5 5 Min. Length 2 Units 6 Max. Length 8 Units 7 Min angle Quad 45 8 Max angle Quad 135 9 Min…

30 Nov 2021 12:43 PM IST

3 Course Certificates

Automotive Sheet Metal Design using Siemens NX CAD / CATIA V5

HyperMesh for FEA Plastic and Sheet Metal Applications

Academic Qualification

B.E

Basaveshwar Engineering College

01 Aug 2015 - 31 May 2019

12th

RLS collage

01 Jun 2013 - 31 May 2015

10th

Swami Vivekanand School Hukkeri

01 Jun 2012 - 31 May 2013

Here are the courses that I have enrolled

Similar Profiles

Ladder of success cannot be climbed with hands in pocket.

The Future in Motion

Give more than what you get you will get more than what you gave

Avid learner