Courses by Software

Courses by Semester

Courses by Domain

Tool-focused Courses

Machine learning

POPULAR COURSES

Success Stories

Week 11 - Simulation of Flow through a pipe in OpenFoam

Aim :- Simulation of Flow through a pipe in OpenFoam. Objective :- Simulate an axi-symmetric flow by applying the wedge boundary condition. Validate results with the Hagen- Poiseuille's equations for the fully developed flow. Also write code in Matlab to automate the generation of blockMeshDict file. …

Suraj Gawali

updated on 24 Aug 2022

Aim :- Simulation of Flow through a pipe in OpenFoam.

Objective :- Simulate an axi-symmetric flow by applying the wedge boundary condition. Validate results with the Hagen- Poiseuille's equations for the fully developed flow. Also write code in Matlab to automate the generation of blockMeshDict file.

Theory :-

Laminar Flow,

Laminar or streamline flow in pipes (or tubes) occurs when a fluid flows in parallel layers, with no disruption between the layers. At low velocities, the fluid tends to flow without lateral mixing, and adjacent layers slide past one another. There are no cross-currents perpendicular to the direction of flow, nor eddies or swirls of fluids. In laminar flow, the motion of the particles of the fluid is very orderly with all particles moving in straight lines parallel to the pipe walls. Any lateral mixing (mixing at right angles to the flow direction) occurs by the action of diffusion between layers of the liquid. Diffusion mixing can be slow however if the diameter of the pipe of the tube is small then this diffusive mixing can be very significant.

Turbulent Flow,

Turbulent flow is a flow regime characterized by chaotic property changes. This includes a rapid variation of pressure and flows velocity in space and time. Turbulent flow is a type of fluid (gas or liquid) flow in which the fluid undergoes irregular fluctuations, or mixing, in contrast to laminar flow, in which the fluid moves in smooth paths or layers. In turbulent flow, the speed of the fluid at a point is continuously undergoing changes in both magnitude and direction.

Reynolds Number,

The Reynolds number is the ratio of inertial forces to viscous forces within a fluid that is subjected to relative internal movement due to different fluid velocities. A region where these forces change behaviour is known as a boundary layer, such as the bounding surface in the interior of a pipe.

The Reynolds number () helps predict flow patterns in different fluid flow situations. At low Reynolds numbers, flows tend to be dominated by laminar (sheet-like) flow, while at high Reynolds numbers flows tend to be turbulent.

Reynolds Number for a internal flow through circular pipe is given as,

Reynolds number for flow through pipes

Laminar flow

Transitional flow

Turbulent Flow

Entrance Length

The entrance length is the distance a flow travels after entering a pipe before the flow becomes fully developed. Entrance length refers to the length of the entry region, the area following the pipe entrance where effects originating from the interior wall of the pipe propagate into the flow as an expanding boundary layer. When the boundary layer expands to fill the entire pipe, the developing flow becomes a fully developed flow, where flow characteristics no longer change with increased distance along the pipe. Many different entrance lengths exist to describe a variety of flow conditions.

The region from the pipe inlet to the point at which the velocity profile is fully developed is called the hydrodynamic entrance region, and the length of this region is called the hydrodynamic entry length .

Velocity profile for Laminar flow

Hagen- Poiseuille's Equation,

where,

ΔP="> = pressure difference between the two ends

= length of pipe

= dynamic viscosity

= volumetric flow rate

= pipe radius

Hagen Poiseuille states that for a specified flow rate, the pressure drops and thus the required pumping power is proportional to the length of the pipe and the viscosity of the fluid, but it is inversely proportional to the fourth power of the radius (or diameter) of the pipe. Therefore, the pumping power requirement for a laminar-flow piping system can be reduced by a factor of 16 by doubling the pipe diameter.

blockMeshDict File in MATLAB,

close all

clear all

clc

%Given Inputs

re=2100; %Reynolds Number

%Assumptions

d=0.0254/2; %Diamter of the Pipe

r=d/2; %Radius of the Pipe

%theta=input("Enter Wedge Angle Less Than 5°=");

theta=2;

%Entry Length for Laminar Flow

l_entry=0.05*re*d; %x-direction or flow direction

l=l_entry+1; %Assuming 1 extra for fully developed flow profile

%Finding the coordinates for the wedge

z=r*sind(theta/2); %z-direction

y=r*cosd(theta/2); %y-direction or radial incase of circular pipe

point0=[0 0 0];

point1=[0 y z];

point2=[0 y -z];

point3=[l 0 0];

point4=[l y z];

point5=[l y -z];

%Creating the blockMeshDict File

f= fopen('blockMeshDict','w');

fprintf(f,'%sn','/*--------------------------------*- C++ -*----------------------------------*');

fprintf(f,'%sn',' ========= |');

fprintf(f,'%sn',' \ / F ield | OpenFOAM: The Open Source CFD Toolbox');

fprintf(f,'%sn',' \ / O peration | Website: https://openfoam.org');

fprintf(f,'%sn',' \ / A nd | Version: 8');

fprintf(f,'%sn',' \/ M anipulation |');

fprintf(f,'%sn','*---------------------------------------------------------------------------*/');

fprintf(f,'%sn','FoamFile');

fprintf(f,'%sn','{');

fprintf(f,'%sn',' version 2.0;');

fprintf(f,'%sn',' format ascii;');

fprintf(f,'%sn',' class dictionary;');

fprintf(f,'%sn',' object blockMeshDict;');

fprintf(f,'%sn','}');

fprintf(f,'%sn','// * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * //');

fprintf(f,'%sn','');

fprintf(f,'%sn','convertToMeters 1;');

fprintf(f,'%sn','');

fprintf(f,'%sn','vertices');

fprintf(f,'%sn','(');

fprintf(f,'t(%f %f %f)n',point0(1),point0(2),point0(3));

fprintf(f,'t(%f %f %f)n',point1(1),point1(2),point1(3));

fprintf(f,'t(%f %f %f)n',point2(1),point2(2),point2(3));

fprintf(f,'t(%f %f %f)n',point3(1),point3(2),point3(3));

fprintf(f,'t(%f %f %f)n',point4(1),point4(2),point4(3));

fprintf(f,'t(%f %f %f)n',point5(1),point5(2),point5(3));

fprintf(f,'%sn',');');

fprintf(f,'%sn','');

fprintf(f,'%sn','blocks');

fprintf(f,'%sn','(');

fprintf(f,'t%sn','hex (0 3 5 2 0 3 4 1) (1000 20 1) simpleGrading (1 0.5 1)');

fprintf(f,'%sn',');');

fprintf(f,'%sn','');

fprintf(f,'%sn','edges');

fprintf(f,'%sn','(');

fprintf(f,'tarc 1 2 (0 %f 0)n',r);

fprintf(f,'tarc 4 5 (%f %f 0)n',l,r);

fprintf(f,'%sn',');');

fprintf(f,'%sn','');

fprintf(f,'%sn','boundary');

fprintf(f,'%sn','(');

fprintf(f,'t%sn','inlet');

fprintf(f,'t%sn','{');

fprintf(f,'tt%sn','type patch;');

fprintf(f,'tt%sn','faces');

fprintf(f,'tt%sn','(');

fprintf(f,'ttt%sn','(0 1 2 0)');

fprintf(f,'tt%sn',');');

fprintf(f,'t%sn','}');

fprintf(f,'t%sn','outlet');

fprintf(f,'t%sn','{');

fprintf(f,'tt%sn','type patch;');

fprintf(f,'tt%sn','faces');

fprintf(f,'tt%sn','(');

fprintf(f,'ttt%sn','(3 5 4 3)');

fprintf(f,'tt%sn',');');

fprintf(f,'t%sn','}');

fprintf(f,'t%sn','top');

fprintf(f,'t%sn','{');

fprintf(f,'tt%sn','type wall;');

fprintf(f,'tt%sn','faces');

fprintf(f,'tt%sn','(');

fprintf(f,'ttt%sn','(1 4 5 2)');

fprintf(f,'tt%sn',');');

fprintf(f,'t%sn','}');

fprintf(f,'t%sn','front');

fprintf(f,'t%sn','{');

fprintf(f,'tt%sn','type wedge;');

fprintf(f,'tt%sn','faces');

fprintf(f,'tt%sn','(');

fprintf(f,'ttt%sn','(0 2 5 3)');

fprintf(f,'tt%sn',');');

fprintf(f,'t%sn','}');

fprintf(f,'t%sn','back');

fprintf(f,'t%sn','{');

fprintf(f,'tt%sn','type wedge;');

fprintf(f,'tt%sn','faces');

fprintf(f,'tt%sn','(');

fprintf(f,'ttt%sn','(0 3 4 1)');

fprintf(f,'tt%sn',');');

fprintf(f,'t%sn','}');

fprintf(f,'t%sn','bottom');

fprintf(f,'t%sn','{');

fprintf(f,'tt%sn','type empty;');

fprintf(f,'tt%sn','faces');

fprintf(f,'tt%sn','(');

fprintf(f,'ttt%sn','(0 3 3 0)');

fprintf(f,'tt%sn',');');

fprintf(f,'t%sn','}');

fprintf(f,'%sn',');');

fprintf(f,'%sn','');

fprintf(f,'%sn','mergePatchPairs');

fprintf(f,'%sn','(');

fprintf(f,'%sn',');');

fprintf(f,'%sn','');

fprintf(f,'%sn','// ************************************************************************* //');

fclose(f);BlockMeshDict Flle,

/*--------------------------------*- C++ -*----------------------------------*\

========= |

\\ / F ield | OpenFOAM: The Open Source CFD Toolbox

\\ / O peration | Website: https://openfoam.org

\\ / A nd | Version: 10

\\/ M anipulation |

\*---------------------------------------------------------------------------*/

FoamFile

{

format ascii;

class dictionary;

object blockMeshDict;

}

// * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * //

convertToMeters 1;

vertices

(

/*0*/(0 0 0)

/*1*/(0 0.009994 0.000349)

/*2*/(0 0.009994 -0.000349)

/*3*/(2.500000 0 0)

/*4*/(2.500000 0.009994 0.000349)

/*5*/(2.500000 0.009994 -0.00349)

);

blocks

(

hex (0 2 1 0 3 5 4 3) (30 1 500) simpleGrading (0.2 1 1)

);

edges

(

arc 2 1 (0 0.010000 0)

arc 5 4 (2.500000 0.010000 0)

);

boundary

(

inlet

{

type patch;

faces

(

(0 1 2 0)

);

}

outlet

{

type patch;

faces

(

(3 5 4 3)

);

}

front

{

type wedge;

faces

(

(0 3 4 1)

);

}

back

{

type wedge;

faces

(

(0 2 5 3)

);

}

pipewall

{

type wall;

faces

(

(1 4 5 2)

);

}

axis

{

type empty;

faces

(

(0 3 3 0)

);

}

);

Simulation Run Step,

ControlDict File,

/*--------------------------------*- C++ -*----------------------------------*\

========= |

\\ / F ield | OpenFOAM: The Open Source CFD Toolbox

\\ / O peration | Website: https://openfoam.org

\\ / A nd | Version: 10

\\/ M anipulation |

\*---------------------------------------------------------------------------*/

FoamFile

{

format ascii;

class dictionary;

location "system";

object controlDict;

}

// * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * //

application icoFoam;

startFrom startTime;

startTime 0;

stopAt endTime;

endTime 0.5;

deltaT 0.0002;

writeControl timeStep;

writeInterval 5;

purgeWrite 0;

writeFormat ascii;

writePrecision 6;

writeCompression off;

timeFormat general;

timePrecision 6;

runTimeModifiable true;

// ************************************************************************* //

Initial and Boundary Conditions,

Pressure :

/*--------------------------------*- C++ -*----------------------------------*\

========= |

\\ / F ield | OpenFOAM: The Open Source CFD Toolbox

\\ / O peration | Website: https://openfoam.org

\\ / A nd | Version: 10

\\/ M anipulation |

\*---------------------------------------------------------------------------*/

FoamFile

{

format ascii;

class volScalarField;

object p;

}

// * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * //

dimensions [0 2 -2 0 0 0 0];

internalField uniform 0;

boundaryField

{

inlet

{

type zeroGradient;

}

outlet

{

type fixedValue;

value uniform 0;

}

front

{

type wedge;

}

back

{

type wedge;

}

axis

{

type empty;

}

pipewall

{

type zeroGradient;

}

}

// ************************************************************************* //

Velocity :

/*--------------------------------*- C++ -*----------------------------------*\

========= |

\\ / F ield | OpenFOAM: The Open Source CFD Toolbox

\\ / O peration | Website: https://openfoam.org

\\ / A nd | Version: 10

\\/ M anipulation |

\*---------------------------------------------------------------------------*/

FoamFile

{

format ascii;

class volVectorField;

object U;

}

// * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * //

dimensions [0 1 -1 0 0 0 0];

internalField uniform (0 0 0);

boundaryField

{

inlet

{

type fixedValue;

value uniform (0.08927 0 0);

}

outlet

{

type zeroGradient;

}

front

{

type wedge;

}

back

{

type wedge;

}

axis

{

type empty;

}

pipewall

{

type noSlip;

}

}

// ************************************************************************* //

Transport Properties File,

/*--------------------------------*- C++ -*----------------------------------*\

========= |

\\ / F ield | OpenFOAM: The Open Source CFD Toolbox

\\ / O peration | Website: https://openfoam.org

\\ / A nd | Version: 10

\\/ M anipulation |

\*---------------------------------------------------------------------------*/

FoamFile

{

format ascii;

class dictionary;

location "constant";

object physicalProperties;

}

// * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * //

nu [0 2 -1 0 0 0 0] 8.90e-4;

// ************************************************************************* //

FVSchemes & FVSolution :

Along with the blockMeshDict and controlD

fvSchemes script file sets the numerical schemes for terms, such as derivatives in equations, that are calculated during a simulation.

FVschemes,

/*--------------------------------*- C++ -*----------------------------------*\

========= |

\\ / F ield | OpenFOAM: The Open Source CFD Toolbox

\\ / O peration | Website: https://openfoam.org

\\ / A nd | Version: 10

\\/ M anipulation |

\*---------------------------------------------------------------------------*/

FoamFile

{

format ascii;

class dictionary;

location "system";

object fvSchemes;

}

// * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * //

ddtSchemes

{

default Euler;

}

gradSchemes

{

default Gauss linear;

grad(p) Gauss linear;

}

divSchemes

{

default none;

div(phi,U) Gauss linear;

}

laplacianSchemes

{

default Gauss linear orthogonal;

}

interpolationSchemes

{

default linear;

}

snGradSchemes

{

default orthogonal;

}

// ************************************************************************* //

FVSolutions,

/*--------------------------------*- C++ -*----------------------------------*\

========= |

\\ / F ield | OpenFOAM: The Open Source CFD Toolbox

\\ / O peration | Website: https://openfoam.org

\\ / A nd | Version: 10

\\/ M anipulation |

\*---------------------------------------------------------------------------*/

FoamFile

{

format ascii;

class dictionary;

location "system";

object fvSolution;

}

// * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * //

solvers

{

p

{

solver PCG;

preconditioner DIC;

tolerance 1e-06;

relTol 0.05;

}

pFinal

{

$p;

relTol 0;

}

U

{

solver smoothSolver;

smoother symGaussSeidel;

tolerance 1e-05;

relTol 0;

}

}

PISO

{

nCorrectors 2;

nNonOrthogonalCorrectors 0;

pRefCell 0;

pRefValue 0;

}

// ************************************************************************* //

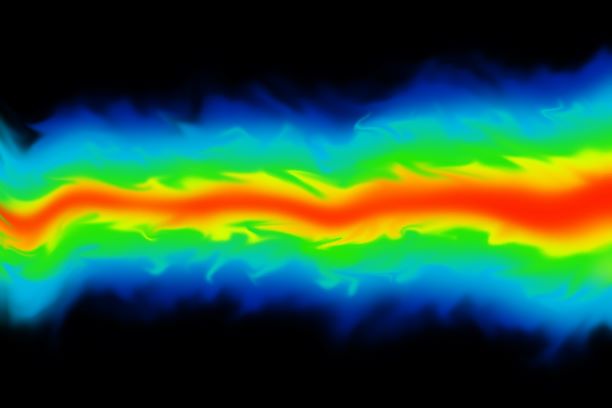

Velocity profile,

Velocity profile and plot,

Leave a comment

Thanks for choosing to leave a comment. Please keep in mind that all the comments are moderated as per our comment policy, and your email will not be published for privacy reasons. Please leave a personal & meaningful conversation.

Other comments...

Be the first to add a comment

Read more Projects by Suraj Gawali (25)

Project 2

Aim :- To find maximum heat generation in the battery pack mathematically and using MATLAB/Simulink. Objective :- The max heat generation of the battery The SOC of the battery at 2 *104second of the battery operation Theory :- SOC Calculation Technique In EV Battery Pack: The State of Charge (SoC) of a battery…

20 Sep 2022 01:46 PM IST

Project 1

Aim :- Design a battery pack for the car with 150Kw capacity. Objective :- Design the battery pack configuration. Draw the BMS topology for this battery pack. Theory :- Battery Management System, A Battery Management System AKA BMS…

19 Sep 2022 01:21 AM IST

Week 11 - Simulation of Flow through a pipe in OpenFoam

Aim :- Simulation of Flow through a pipe in OpenFoam. Objective :- Simulate an axi-symmetric flow by applying the wedge boundary condition. Validate results with the Hagen- Poiseuille's equations for the fully developed flow. Also write code in Matlab to automate the generation of blockMeshDict file. …

24 Aug 2022 06:45 AM IST

Week 9 - FVM Literature Review

Aim :- Introduction to Finite Volume Method. Objective :- Explain what is FVM. State major differences between FDM & FVM. Describe the need for interpolation schemes and flux limiters in FVM. Theory :- Finite Volume Method, The finite volume method (FVM) is a method for representing…

19 Aug 2022 07:34 AM IST

Related Courses

Skill-Lync offers industry relevant advanced engineering courses for engineering students by partnering with industry experts.

Our Company

4th Floor, BLOCK-B, Velachery - Tambaram Main Rd, Ram Nagar South, Madipakkam, Chennai, Tamil Nadu 600042.

Top Individual Courses

Top PG Programs

Skill-Lync Plus

Trending Blogs

© 2025 Skill-Lync Inc. All Rights Reserved.