Courses by Software

Courses by Semester

Courses by Domain

Tool-focused Courses

Machine learning

POPULAR COURSES

Success Stories

Project 2

Aim :- To find maximum heat generation in the battery pack mathematically and using MATLAB/Simulink. Objective :- The max heat generation of the battery The SOC of the battery at 2 *104second of the battery operation Theory :- SOC Calculation Technique In EV Battery Pack: The State of Charge (SoC) of a battery…

Suraj Gawali

updated on 20 Sep 2022

Aim :- To find maximum heat generation in the battery pack mathematically and using MATLAB/Simulink.

Objective :-

- The max heat generation of the battery

- The SOC of the battery at 2 *104second of the battery operation

Theory :-

SOC Calculation Technique In EV Battery Pack:

The State of Charge (SoC) of a battery cell is required to maintain it’s safe operation and lifetime during charge, discharge and storage. However, SoC cannot be measured directly and is estimated from other measurements and known parameters. This leads to errors in the estimated SoC and that means it is not possible to fully exploit the full capability of the cell.

Battery pack SoC measurement/estimation methods [2]:

- Direct measurement

- Open circuit voltage

- Terminal voltage

- Impedance

- Impedance spectroscopy

- 3rd electrode

- Book-keeping estimation

- Coulomb counting

- Modified Coulomb counting

- Adaptive systems

- BP neural network

- RBF neural network

- Support vector machine

- Fuzzy neural network

- Kalman filter

- Hybrid methods

- Coulomb counting and EMF combination

- Coulomb counting and Kalman filter combination

- Per-unit system and EKF combination

The two common forms of SoC tracking in battery management systems are voltage profiling and coulomb counting.

- Voltage Profiling,

Using the Open Circuit Voltage curve as a reference it is possible to measure the voltage of a cell and hence lookup the SoC. The significant issue with Voltage Profiling is that this relies on the OCV curve and this is defined based on a cell that has been at rest for some time. Essentially because the chemical reactions in the cell take time to come to equilibrium, especially after a high current demand. Hence the BMS needs to identify and wait for the cell to come to rest. Or the BMS has to estimate the OCV from the internal resistance of the cell. This adds another level of errors.

- Coulomb Counting,

The coulomb counting method, also known as ampere hour counting and current integration, is the most common technique for calculating the SOC. This method employs battery current readings mathematically integrated over the usage period to calculate SOC values. The coulomb counting method then calculates the remaining capacity simply by accumulating the charge transferred in or out of the battery. The accuracy of this method resorts primarily to a precise measurement of the battery current and accurate estimation of the initial SOC. With a preknown capacity, which might be memorized or initially estimated by the operating conditions, the SOC of a battery can be calculated by integrating the charging and discharging currents over the operating periods. However, the releasable charge is always less than the stored charge in the charging and discharging cycle. In other words, there are losses during charging and discharging. These losses, in addition with the self discharging, cause accumulating errors. For more precise SOC estimation, these factors should be taken into account. In addition, the SOC should be recalibrated on a regular basis and the declination of the releasable capacity should be considered for more precise estimation.

Heat Generation In Battery Pack:

There are two primary sources of internal heat generation in electrochemical cells and batteries during their operation:

● Heat from the electrochemical reactions

● Heat from polarization

Batteries are defined as being made up of multiple electrochemical cells. Thus, the cell is the basic building block.

The cell is also the entity to which the thermodynamic principles apply. Thus, the derivation of the fundamental equations will focus on the individual cell, recognizing that the quantity and rate of heat generation or absorption ultimately calculated can be readily scaled to multi-cell batteries.

Calculation :-

Max Heat Generation by the Battery Pack,

Max Heat Generated = Max Joule Heat + Max Entropic Heat

Joule Heat =

Entropic Factor/Heat = 2

Battery Resistance = 0.5 mOhm

Max Joule Heat =

= 1.164 J

Max Heat Generated = 1.164 + 2 -(Given Entropic Factor/Heat = 2)

= 3.164 J

SOC of the battery at 2 *104second of the battery operation:

Simulink Model,

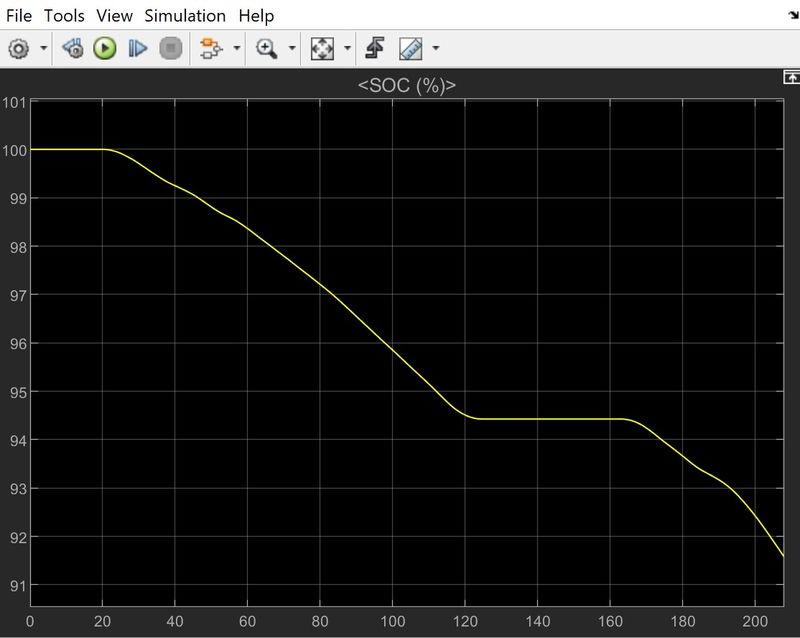

Actual Drive Cycle Output for 208 sec,

Result (SOC),

Conclusion:

Here we can see that SOC% of the battery pack gets drop after using battery for 208 seconds. Initially it was 100% and gets drop to 91.05%

Leave a comment

Thanks for choosing to leave a comment. Please keep in mind that all the comments are moderated as per our comment policy, and your email will not be published for privacy reasons. Please leave a personal & meaningful conversation.

Other comments...

Be the first to add a comment

Read more Projects by Suraj Gawali (25)

Project 2

Aim :- To find maximum heat generation in the battery pack mathematically and using MATLAB/Simulink. Objective :- The max heat generation of the battery The SOC of the battery at 2 *104second of the battery operation Theory :- SOC Calculation Technique In EV Battery Pack: The State of Charge (SoC) of a battery…

20 Sep 2022 01:46 PM IST

Project 1

Aim :- Design a battery pack for the car with 150Kw capacity. Objective :- Design the battery pack configuration. Draw the BMS topology for this battery pack. Theory :- Battery Management System, A Battery Management System AKA BMS…

19 Sep 2022 01:21 AM IST

Week 11 - Simulation of Flow through a pipe in OpenFoam

Aim :- Simulation of Flow through a pipe in OpenFoam. Objective :- Simulate an axi-symmetric flow by applying the wedge boundary condition. Validate results with the Hagen- Poiseuille's equations for the fully developed flow. Also write code in Matlab to automate the generation of blockMeshDict file. …

24 Aug 2022 06:45 AM IST

Week 9 - FVM Literature Review

Aim :- Introduction to Finite Volume Method. Objective :- Explain what is FVM. State major differences between FDM & FVM. Describe the need for interpolation schemes and flux limiters in FVM. Theory :- Finite Volume Method, The finite volume method (FVM) is a method for representing…

19 Aug 2022 07:34 AM IST

Related Courses

Skill-Lync offers industry relevant advanced engineering courses for engineering students by partnering with industry experts.

Our Company

4th Floor, BLOCK-B, Velachery - Tambaram Main Rd, Ram Nagar South, Madipakkam, Chennai, Tamil Nadu 600042.

Top Individual Courses

Top PG Programs

Skill-Lync Plus

Trending Blogs

© 2025 Skill-Lync Inc. All Rights Reserved.