Courses by Software

Courses by Semester

Courses by Domain

Tool-focused Courses

Machine learning

POPULAR COURSES

Success Stories

Fender Design Challenge

DESIGN OF FRONT FENDER OBJECTIVE: To design the car front fender FENDER: American English term for the part of an automobile, motorcycle or other vehicle body that frames a wheel well (the fender underside). Its primary purpose is to prevent sand, mud, rocks, liquids, and other road spray from being thrown into the air…

Bhanusekar Murugadoss

updated on 22 Oct 2021

DESIGN OF FRONT FENDER

OBJECTIVE: To design the car front fender

FENDER: American English term for the part of an automobile, motorcycle or other vehicle body that frames a wheel well (the fender underside). Its primary purpose is to prevent sand, mud, rocks, liquids, and other road spray from being thrown into the air by the rotating tire.

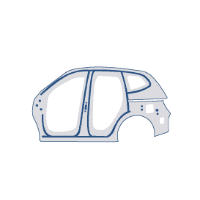

DESIGN CONSIDERATIONS:

Dimensions should be considered as shown in figure

There are 5 mounting regions on the fender

- pillar mounting

- Body mounting

- Sill mounting

- Bumper mounting

- Drip mounting

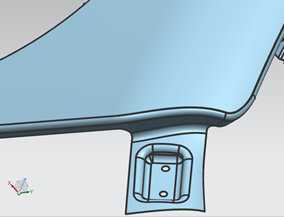

DESIGN 0F DRIP AREA MOUNTING:

It is the important mounting of the fender. This is connected with the engine compartment, therefore the lot of constraints are to be followed while designing the fender

Note: It should be 150mm apart from the edge so that it won’t get disturbed by lamp mountings

- Darts are added on the longer side of the drip area in order to provide the stiffness and add strength to the part. It Play a main role by avoiding vibration and forces from outside

- Embossing are provided on the mounting to strengthen them during fastening

DESIGN OF BUMPER MOUNTING

Bumper mounting area is to fix the bumper to the fender with the help of the fasteners or equivalent nuts

DESIGN OF A-PILLAR MOUNTING:

This is a structural pillar that combines the body to the roof. It makes the sides of the windshield at rest and front fenders are fastened

Design of Sill Mounting:

Sill is the panel directly below the bottom of the door supporting the floor and may be used to combine the floor and the body . The bottom end of the fender is mounted on the sill body for reinforcement of the fender

DESIGN OF BAFFLE MOUNTING:

Baffle mounting or mudguard are clip fit type of mounting on the inner side of the fender arch over the Tire. It protects the car engine compartment and pedestrians from causing injuries from chip out debris on the road when the car is in motion. They are mounted on the fender using locking clips.

Thicken The Fender for 0.75mm

Feature Tree

Conclusion

Thus Designing a fender has been accomplished

Leave a comment

Thanks for choosing to leave a comment. Please keep in mind that all the comments are moderated as per our comment policy, and your email will not be published for privacy reasons. Please leave a personal & meaningful conversation.

Other comments...

Be the first to add a comment

Read more Projects by Bhanusekar Murugadoss (11)

Fender Design Challenge

DESIGN OF FRONT FENDER OBJECTIVE: To design the car front fender FENDER: American English term for the part of an automobile, motorcycle or other vehicle body that frames a wheel well (the fender underside). Its primary purpose is to prevent sand, mud, rocks, liquids, and other road spray from being thrown into the air…

22 Oct 2021 01:17 PM IST

Section Modulus calculation and optimization

AIM: To generate the report on finding the section modulus for the Hood design and improve its strength by optimization. SECTION MODULUS: It is a geometric property for a given cross-section used in the design of beams or flexural members If the section modulus increases the moment of resistance increases and…

26 Aug 2021 02:25 PM IST

Hood design-Week 2

Designing and Assembling of Hood Introduction Hood Often called as Bonnet which is situated in front side of Cars. They mainly are for closure of Engine compartments and component which is situated at the front side. They also serve a purpose of protecting passenger inside the car and pedestrians during the event of…

13 Aug 2021 02:49 PM IST

Benchmarking

Bench Marking I Observation for the Requirement Highly crowded city 5 Members in family Long travel – Every Month Daily usage Budget Min 8L Max 10L Plan on the Requirement On regards with the first point it is highly recommended to go on Automatic to avoid the strain in driving Highly prefer Sedan type…

13 Jun 2021 09:33 AM IST

Related Courses

127 Hours of Content

Skill-Lync offers industry relevant advanced engineering courses for engineering students by partnering with industry experts.

Our Company

4th Floor, BLOCK-B, Velachery - Tambaram Main Rd, Ram Nagar South, Madipakkam, Chennai, Tamil Nadu 600042.

Top Individual Courses

Top PG Programs

Skill-Lync Plus

Trending Blogs

© 2025 Skill-Lync Inc. All Rights Reserved.