Courses by Software

Courses by Semester

Courses by Domain

Tool-focused Courses

Machine learning

POPULAR COURSES

Success Stories

Week 1- Mixing Tee

This assignment aims to evaluate the mixing effectiveness of a Tee joint with two different outlet pipe lengths, namely small and long. The required Tee geometry is provided, and the interior volume for CFD analysis is extracted as shown below. Tee geometry with shorter outlet pipe: Extracted…

Jaswanth Kalyan Kumar Alapati

updated on 03 Sep 2022

This assignment aims to evaluate the mixing effectiveness of a Tee joint with two different outlet pipe lengths, namely small and long.

The required Tee geometry is provided, and the interior volume for CFD analysis is extracted as shown below.

Tee geometry with shorter outlet pipe:

Extracted volume:

The meshing of the geometry is performed in ANSYS fluent module. First, a default mesh is generated for the analysis, followed by a mesh-independent study.

The problem is defined below:

The temperature and velocities of the fluid entering the hot and cold inlets are different and are described in the table below.

| Inlet type | Temperature (Centigrade) | Velocity () |

| Cold | 19 | 6 |

| Hot | 36 | 3 |

Momentum ratio, defined as is varied as 2 & 4 with hot inlet velocity fixed at 36 resulting in the cold velocity as 6 & 12 respectively.

As shown in the previous image, the boundary conditions are named appropriately, with velocity inlets, the pressure outlet, and the outer surface as a wall.

The energy option is selected with K-epsilon (realizable, standard wall functions) as the turbulence model. All other options are used as default with the residuals decreased than the default for a better solution.

New definitions like area-weighted average and standard deviation of the outlet temperature are defined to evaluate the mixing efficiency. A mesh-independent study is performed for the shorter outlet pipe by changing the element size, and the results are tabulated below.

For shorter outlet pipe with momentum ratio = 2:

| Element size (m) | Tetrahedral elements | Area weighted outlet temperature (Centigrade) |

| 0.010219 | 12759 | 30.202037 |

| 0.005 | 14400 | 30.235698 |

| 0.0025 | 60959 | 30.306484 |

| 0.0015 | 212192 | 30.343242 |

The analytical values for the outlet temperature, calculated for different momentum ratios, are shown below.

| Momentum ratio |

Outlet temperature (Centigrade) |

| 2 | 30.32238 |

| 4 | 27.4876 |

From the above tables, the error in the outlet temperature is less for the fourth case (0.0015 m as the element size). Hence, this mesh is considered for the study.

A different turbulence model (K- SST) is also tested, and the outlet temperature is listed below.

| Turbulence model |

Outlet temperature (Centigrade) |

|

K- (realizable, standard wall functions) |

30.343242 |

| (K- SST) | 30.49841 |

The outlet temperature (area-weighted) is closer to the theoretical value for the K- model. So, this turbulence model is used for the study.

Shorter outlet pipe, momentum ratio = 2:

Convergence plot

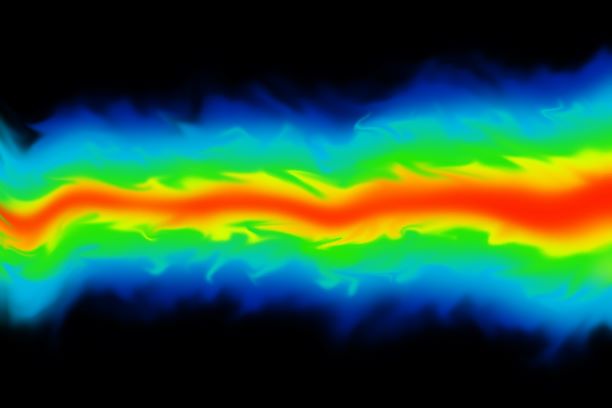

Temperature & velocity plot along the axial plane

Shorter outlet pipe, momentum ratio = 4:

Longer outlet pipe, momentum ratio = 2:

Shorter outlet pipe, momentum ratio = 4:

The results are summarized in the following table

| Geometry | Momentum ratio | Area-weighted outlet temperature |

| Short | 2 | 30.343242 |

| Long | 2 | 30.442305 |

| Short | 4 | 27.580206 |

| Long | 4 | 27.500309 |

The centreline temperature variation for all four cases is plotted below.

Cases 1 & 2 represent flows with momentum ratio 2 & 4 respectively.

In short, it can be concluded that increasing the outlet pipe length indeed increases the mixing efficiency even though the increase with respect to a shorter outlet pipe is less.

Leave a comment

Thanks for choosing to leave a comment. Please keep in mind that all the comments are moderated as per our comment policy, and your email will not be published for privacy reasons. Please leave a personal & meaningful conversation.

Other comments...

Be the first to add a comment

Read more Projects by Jaswanth Kalyan Kumar Alapati (8)

Week 1- Mixing Tee

This assignment aims to evaluate the mixing effectiveness of a Tee joint with two different outlet pipe lengths, namely small and long. The required Tee geometry is provided, and the interior volume for CFD analysis is extracted as shown below. Tee geometry with shorter outlet pipe: Extracted…

03 Sep 2022 08:13 PM IST

Week 12 - Validation studies of Symmetry BC vs Wedge BC in OpenFOAM vs Analytical H.P equation

Unlike in the previous assignment, where the simulation is performed using a transient solver icoFoam, the simulation is carried out using a steady-state solver simpleFoam since the emphasis is on the steady-state flow field. This assignment aims to compare the boundary conditions of Wedge and Symmetry…

11 Jan 2022 11:09 AM IST

Week 11 - Simulation of Flow through a pipe in OpenFoam

The following is the simulation of a laminar flow of an incompressible fluid through the pipe in OpenFoam. The following figure depicts the physical situation of the flow. For a laminar flow, the hydrodynamic length, , where is pipe diameter, and is Reynolds number…

07 Jan 2022 10:13 AM IST

Week 9 - FVM Literature Review

Finite Volume Method (FVM) is a numerical technique for solving partial differential equations governing the phenomena. The method involves discretizing the domain into smaller volumes. These control volumes are connected by common faces. The governing equation in integral form is applied for all the control volumes followed…

26 Dec 2021 07:15 AM IST

Related Courses

Skill-Lync offers industry relevant advanced engineering courses for engineering students by partnering with industry experts.

Our Company

4th Floor, BLOCK-B, Velachery - Tambaram Main Rd, Ram Nagar South, Madipakkam, Chennai, Tamil Nadu 600042.

Top Individual Courses

Top PG Programs

Skill-Lync Plus

Trending Blogs

© 2025 Skill-Lync Inc. All Rights Reserved.