Courses by Software

Courses by Semester

Courses by Domain

Tool-focused Courses

Machine learning

POPULAR COURSES

Success Stories

Gate Valve Parametric Study

Aim : To perform a parametric study for gate valve simulation at various opening configuration from 10% to 80% Spaceclaim : The given geometry is imported in space claim The two flanges are extended on both directions using the boss extrude tool Volume is extracted using the volume extract option…

Ajitesh Rajkumar

updated on 16 Nov 2020

Aim :

To perform a parametric study for gate valve simulation at various opening configuration from 10% to 80%

Spaceclaim :

- The given geometry is imported in space claim

- The two flanges are extended on both directions using the boss extrude tool

- Volume is extracted using the volume extract option . Prepare >> Volume extract >> By edge

- Other parts of the gate valve are suppressed for physics, only the fluid volume is sent to meshing interface

Meshing :

- Before meshing, the inlet and outlet are named respectively using named selections

- The meshing is done with a total element size of 152852 elements

- The element sizing is given as 92 mm

- The mesh is then updated and transitioned into fluent.

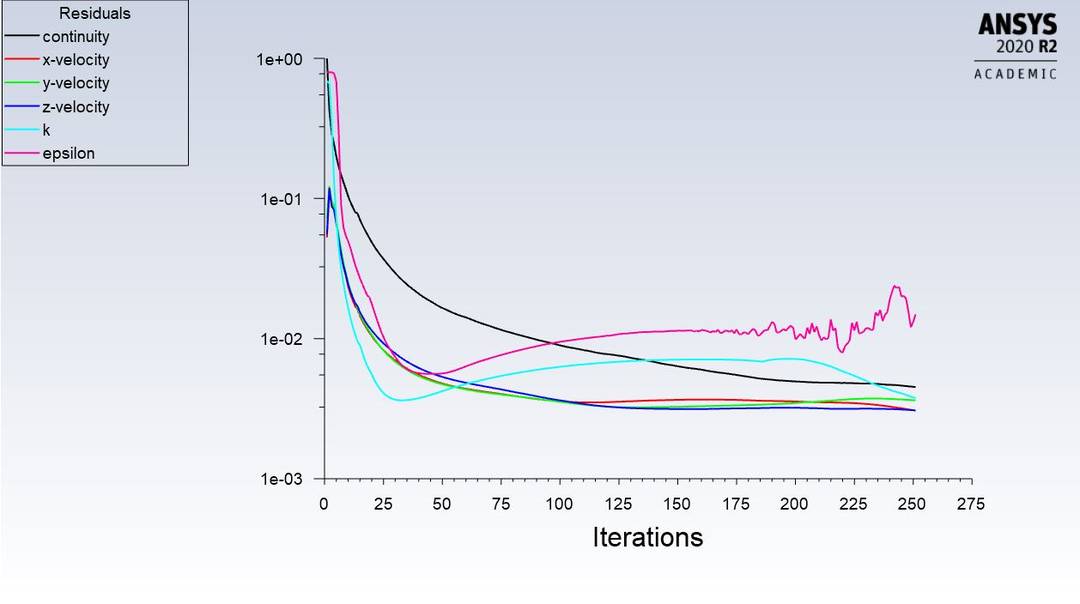

Fluent:

Solver: Pressure based

Time: Steady state

Gravity : - 9.81 m/s2 on Z axis

Viscous model : K-epsilom Standard wall function

Inlet pressure : 10 Pascals

- For 10mm Valve lift

- For 20mm Valve lift

- For 30mm Valve lift

- For 50mm Valve lift

- For 60mm Valve lift

- For 80mm Valve lift

- For 90mm Valve lift

Flow Coeffecient

The flow coefficient of a device is a relative measure of its efficiency at allowing fluid flow. It describes the relationship between the pressure drop across an orifice valve or other assembly and the corresponding flow rate.

Mathematically the flow coefficient Cv (or flow-capacity rating of valve) can be expressed as :

where:

- Q is the rate of flow (expressed in US gallons per minute),

- SG is the specific gravityof the fluid (for water = 1),

- ΔP is the pressure drop across the valve (expressed in psi).

In more practical terms, the flow coefficient Cv is the volume (in US gallons) of water at 60 °F that will flow per minute through a valve with a pressure drop of 1 psi across the valve.

The use of the flow coefficient offers a standard method of comparing valve capacities and sizing valves for specific applications that is widely accepted by industry. The general definition of the flow coefficient can be expanded into equations modeling the flow of liquids, gases and steam using the discharge coeffecient

Flow Factor :

The metric equivalent flow factor (Kv; commonly used everywhere else in the world with the exception of the United States) is calculated using metric units

Kv = 0.865 Cv

Flow Coeffecient Vs Flow factor

Conclusion :

We can see from the data , that the mass flow rate increases with increase in the valve opening. This inturn increases the Flow coeffecient and flow factor .

Leave a comment

Thanks for choosing to leave a comment. Please keep in mind that all the comments are moderated as per our comment policy, and your email will not be published for privacy reasons. Please leave a personal & meaningful conversation.

Other comments...

Be the first to add a comment

Read more Projects by Ajitesh Rajkumar (10)

Independent Research Project

AIM: To simulate the conjugate heat transfer in a rectangular channel and to calculate the nusslet number and skin friction coeffecient. ANALYSIS PERFORMED: Temperature distribution Velocity of fluid flow Average Nusslet Number Skin friction Coeffecient DESCRIPTION: …

27 Jun 2021 03:25 PM IST

Challenge on Combustion

Aim : Perform a combustion simulation on the combustor model and plot the variation of the mass fraction of the different species’ in the simulation using line probes at different locations of the combustor. Space Claim : The given combustor model is first imported into spaceclaim The imported model…

26 Dec 2020 10:36 AM IST

Gate Valve Parametric Study

Aim : To perform a parametric study for gate valve simulation at various opening configuration from 10% to 80% Spaceclaim : The given geometry is imported in space claim The two flanges are extended on both directions using the boss extrude tool Volume is extracted using the volume extract option…

16 Nov 2020 07:04 AM IST

Efficiency Analysis on Cyclone Seperator

Aim: To perform an analysis on a cyclone seperator model at various partice size from 1 μm to 5 μm and to identify the seperation efficiency. To perform the same analysis by varying the particle velocity from 1 m/sec to 5 m/sec Emprical…

06 Sep 2020 08:25 AM IST

Related Courses

0 Hours of Content

Skill-Lync offers industry relevant advanced engineering courses for engineering students by partnering with industry experts.

Our Company

4th Floor, BLOCK-B, Velachery - Tambaram Main Rd, Ram Nagar South, Madipakkam, Chennai, Tamil Nadu 600042.

Top Individual Courses

Top PG Programs

Skill-Lync Plus

Trending Blogs

© 2025 Skill-Lync Inc. All Rights Reserved.