Courses by Software

Courses by Semester

Courses by Domain

Tool-focused Courses

Machine learning

POPULAR COURSES

Success Stories

Challenge on Combustion

Aim : Perform a combustion simulation on the combustor model and plot the variation of the mass fraction of the different species’ in the simulation using line probes at different locations of the combustor. Space Claim : The given combustor model is first imported into spaceclaim The imported model…

Ajitesh Rajkumar

updated on 26 Dec 2020

Aim :

Perform a combustion simulation on the combustor model and plot the variation of the mass fraction of the different species’ in the simulation using line probes at different locations of the combustor.

Space Claim :

- The given combustor model is first imported into spaceclaim

- The imported model will have three seperate geometry, all the geometry need to be combined using the combine tool present on the Design tab

- Affter combining the model to form a single solid, the body is split into two along the plane in Z- axis and Y axis, using the split body command on the design tab.

- Once the body is split, we can get a 2-D geometry of our combustor module.We are using a 2-D model since the entire model will involve more cell count.

Meshing :

- The 2D geometry from the Spaceclaim is then transitioned into Meshing interface.

- The Boundaries are named as Air inlet , fuel inlet , walls and axis using the named selections command

- The meshing is done with a mesh size of 2.5mm

- The mesh is then updated for transitioning into Fluent

Fluent :

The mesh is then transitioned into fluent, double precision and two parallel processors are used for solving

Setup :

- Energy : ON

- Viscous model : K- Epsilon standard wall function model

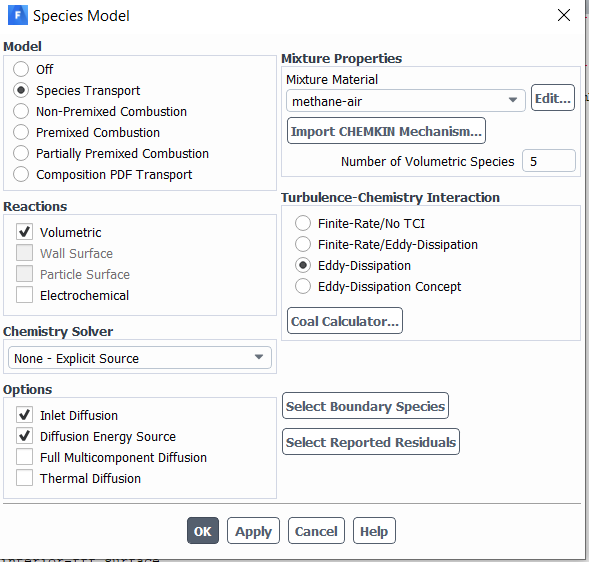

- Species model : Species transport

- Nox model : Thermal Nox and Fuel Nox

- SOOT model : One step

EDDY-Dissipation model : The eddy dissipation model, based on the work of Magnussen and Hjertager, is a turbulent-chemistry reaction model. Most fuels are fast burning and the overall rate of reaction is controlled by turbulence mixing. In the non-premixed flames, turbulence slowly mixes the fuel and oxidizer into the reaction zones where they burn quickly. In premixed flames the turbulence slowly mixes cold reactants and hot products into the reaction zones where reaction occurs rapidly. In such cases the combustion is said to be mixing-limited, and the complex and often unknown chemical kinetics can be safely neglected. In this model, the chemical reaction is governed by large eddy mixing time scale. Combustion initiates whenever there is turbulence present in the flow. It does not need an ignition source to initiate the combustion. This type of model is valid for the non-premixed combustion, but for the premixed flames the reactant is assumed to burn at the moment it enters the computation model, which is a shortcoming of this model as in practice the reactant needs some time to get to the ignition temperature to initiate the combustion

Boundary conditions :

- Air Inlet Velocity : 0.5 m/s

- Air Inlet Species : O2 - 0.23 Mass fractions

- Fuel Inlet Velocity : 80 m/s

- Fuel Inlet Species : CH4- 1 Mass fractions

After the following setup is done, the simulation is done for 500 iterations

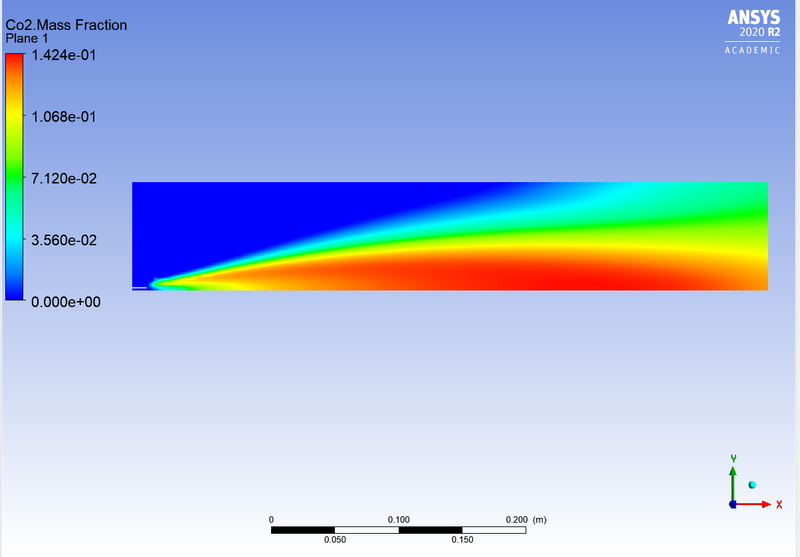

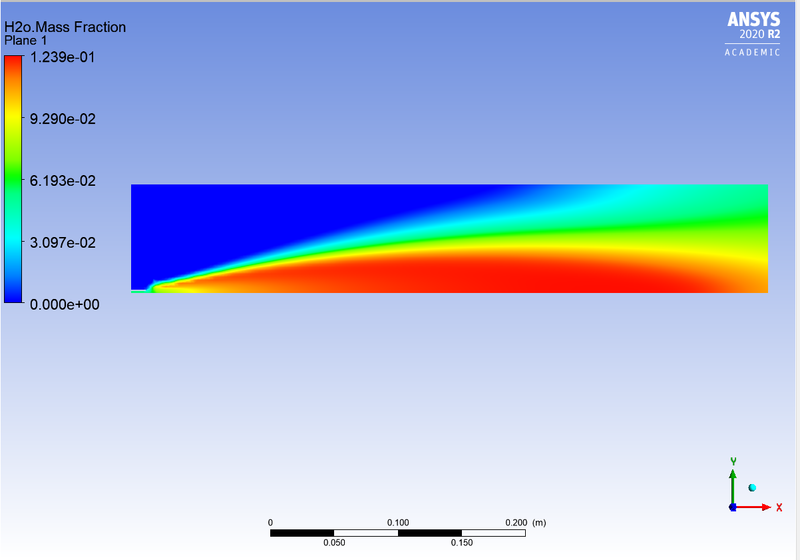

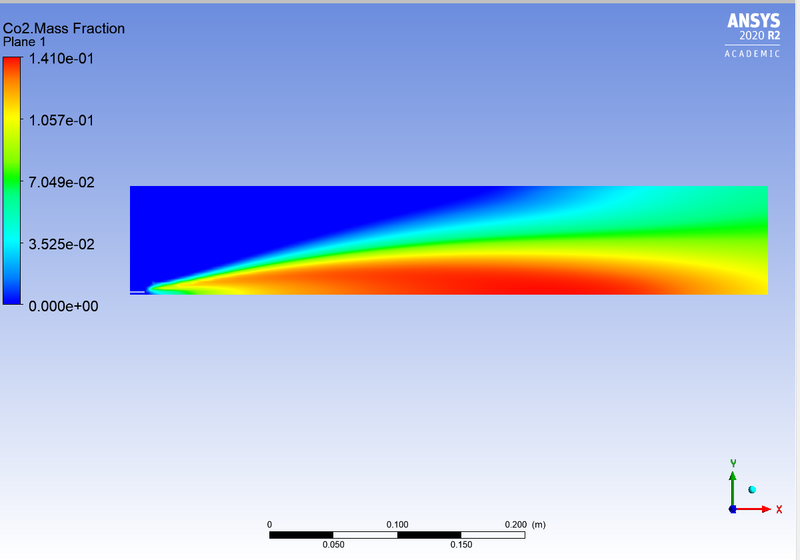

Post Processor :

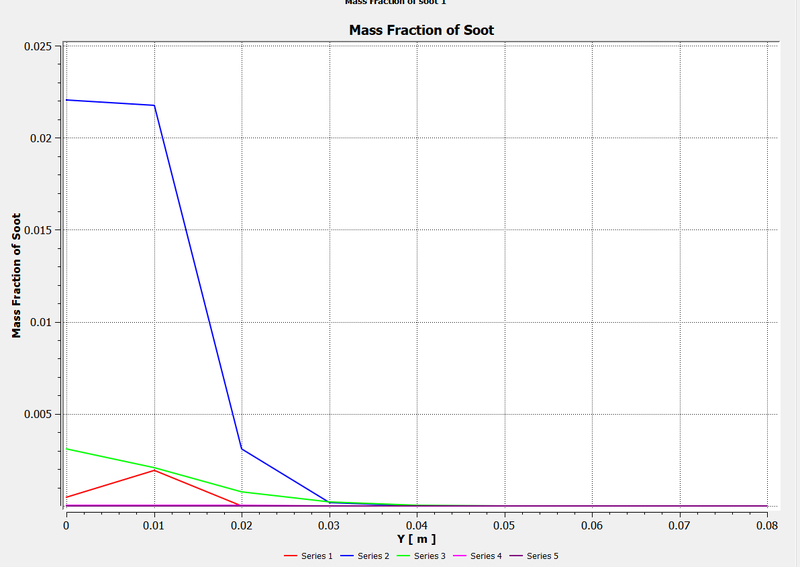

- In the post processor, line probes are used and located in the model at various intervals to mointor the behaviour of vatious species .

- The distribution of mass fraction of different species can be visualised using the below plot

When we compare the temperature contour and NOx mass fraction , we can see that the NOx has been formed at the region where the temperature is high, theoretically and experimenteally we know that NOx forms at high temperature. This helps us to prove that, the setup is correct

PART 2 :

As we can see from the Plot for Mass fraction of Soot, we can find that the amount of Soot produced is one a higher side at 8.857 e-02

The stringent government norms also demand the least formation of Nox and soot and to satisfy those requirements, you need to check the effect of adding the water in the fuel.

Case 1: 5% water added to fuel

Case 2: 10% water added to fuel

Case 3 : 15% water added to fuel

From the above cases, by adding H2O with the fuel, we were able to reduce the Nox content and Soot significantly

The consolidated data is shown above, the data before adding water to Fuel inlet can be obtained from the previous Cases

| Percent Water | 0 | 5 | 10 | 15 | |

| Mass Fraction of O2 | 0.008357 | 0.00043047 | 0.00024061 | 0.00011156 | |

We can see from this chart the gradual decrease in soot .

Leave a comment

Thanks for choosing to leave a comment. Please keep in mind that all the comments are moderated as per our comment policy, and your email will not be published for privacy reasons. Please leave a personal & meaningful conversation.

Other comments...

Be the first to add a comment

Read more Projects by Ajitesh Rajkumar (10)

Independent Research Project

AIM: To simulate the conjugate heat transfer in a rectangular channel and to calculate the nusslet number and skin friction coeffecient. ANALYSIS PERFORMED: Temperature distribution Velocity of fluid flow Average Nusslet Number Skin friction Coeffecient DESCRIPTION: …

27 Jun 2021 03:25 PM IST

Challenge on Combustion

Aim : Perform a combustion simulation on the combustor model and plot the variation of the mass fraction of the different species’ in the simulation using line probes at different locations of the combustor. Space Claim : The given combustor model is first imported into spaceclaim The imported model…

26 Dec 2020 10:36 AM IST

Gate Valve Parametric Study

Aim : To perform a parametric study for gate valve simulation at various opening configuration from 10% to 80% Spaceclaim : The given geometry is imported in space claim The two flanges are extended on both directions using the boss extrude tool Volume is extracted using the volume extract option…

16 Nov 2020 07:04 AM IST

Efficiency Analysis on Cyclone Seperator

Aim: To perform an analysis on a cyclone seperator model at various partice size from 1 μm to 5 μm and to identify the seperation efficiency. To perform the same analysis by varying the particle velocity from 1 m/sec to 5 m/sec Emprical…

06 Sep 2020 08:25 AM IST

Related Courses

0 Hours of Content

Skill-Lync offers industry relevant advanced engineering courses for engineering students by partnering with industry experts.

Our Company

4th Floor, BLOCK-B, Velachery - Tambaram Main Rd, Ram Nagar South, Madipakkam, Chennai, Tamil Nadu 600042.

Top Individual Courses

Top PG Programs

Skill-Lync Plus

Trending Blogs

© 2025 Skill-Lync Inc. All Rights Reserved.