Courses by Software

Courses by Semester

Courses by Domain

Tool-focused Courses

Machine learning

POPULAR COURSES

Success Stories

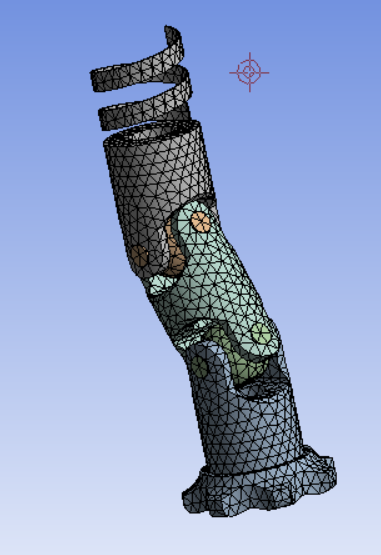

Week 8 - Universal Joint

Objective of challenge: To perform a transient structural analysis on a double universal joint with a spring using three different materials i.e. Structural Steel, Stainless Steel and Titanium alloy, The three materials must be used on the joint with the springs alone. Find out the values of Equivalent stress and total…

Chiranjeevi ADDURI

updated on 14 Mar 2021

Objective of challenge: To perform a transient structural analysis on a double universal joint with a spring using three different materials i.e. Structural Steel, Stainless Steel and Titanium alloy, The three materials must be used on the joint with the springs alone. Find out the values of Equivalent stress and total deformation.

Simulation setup configuration as follows:

1. Model as follows

2. Part names are specified as

3. Material applied are

Case 1

Case 2

Case 3

4. Connections configured as

5. Mesh size is configured as

6. Analysis settings are configured as

Transient simulation results are as follows:

| Description | Case 1 (Structural Steel) | Case 2 (Stainless Steel) | Case 3 (Titanium alloy) |

| Equivalent stress | Max 1639.9 Mpa |

Max 1588.4 Mpa |

Max 802.53 Mpa |

| Total deformation (Joint spring) | Max 25.575 mm |

Max 25.571 mm |

Max 25.562mm |

| Total deformation | Max 38.637 mm |

Max 38.637 mm |

Max 38.637 mm |

| Conclusion | 1. Found no difference in values of Total deformation. 2. Found less equivalent stress in "Titanium alloy" compared to Structural steel and Stainless steel. |

||

Leave a comment

Thanks for choosing to leave a comment. Please keep in mind that all the comments are moderated as per our comment policy, and your email will not be published for privacy reasons. Please leave a personal & meaningful conversation.

Other comments...

Be the first to add a comment

Read more Projects by Chiranjeevi ADDURI (17)

Week 11 Car Crash simulation

Objective of challenge: To perform a Explicit dynamic analysis of a Car Crash, a parametric study using 3 different values of thickness for the car body. Need to apply the same conditions as per the video. Find out total deformation and Equivalent stresses acting on the model. Simulation setup configuration as follows:…

31 Mar 2021 09:32 AM IST

Week 10 Bullet penetrating a Bucket Challenge

Objective of challenge: To perform a Explicit dynamic analysis of a bullet penetrating into a bucket by using 3 different non linear materials for the bucket. Analyse their behaviour with velocity and conditions for bullet as per training video. To attach an animation for the three cases. Simulation setup configuration…

26 Mar 2021 10:22 AM IST

Week 9 Machining with Planer Challenge

Objective of challenge: To perform a Explicit dynamic analysis of Machining with Planer with a cutting velocity of 20000mm/s and the other will be with a cutting velocity of 15000mm/s. Find out the Equivalent Stress, Total Deformation and also insert a User defined result to calculate the temperature of the body. Simulation…

25 Mar 2021 08:33 AM IST

Week 4 -Wire Bending Challenge

Objective of challenge: To perform the simulation of the bending of a wire by applying materials of Copper Alloy (Non Linear), Aluminium Alloy (Non Linear) and Magnesium Alloy ( Non Linear) for the wire alone. Find out the Equivalent stress and Equivalent strain on the wire alone. Simulation setup configuration as follows:…

20 Mar 2021 04:43 PM IST

Related Courses

0 Hours of Content

Skill-Lync offers industry relevant advanced engineering courses for engineering students by partnering with industry experts.

Our Company

4th Floor, BLOCK-B, Velachery - Tambaram Main Rd, Ram Nagar South, Madipakkam, Chennai, Tamil Nadu 600042.

Top Individual Courses

Top PG Programs

Skill-Lync Plus

Trending Blogs

© 2025 Skill-Lync Inc. All Rights Reserved.