Courses by Software

Courses by Semester

Courses by Domain

Tool-focused Courses

Machine learning

POPULAR COURSES

Success Stories

Week 10 - Simulating Combustion of Natural Gas.

The following objectives were undertaken during this project:- Part I Perform a combustion simulation on the combustor model and plot the variation of the mass fraction of the different species in the simulation using line probes at different locations of the combustor as shown in Fig. You need to plot for CO2,…

mohit tiwari

updated on 13 Apr 2021

The following objectives were undertaken during this project:-

Part I

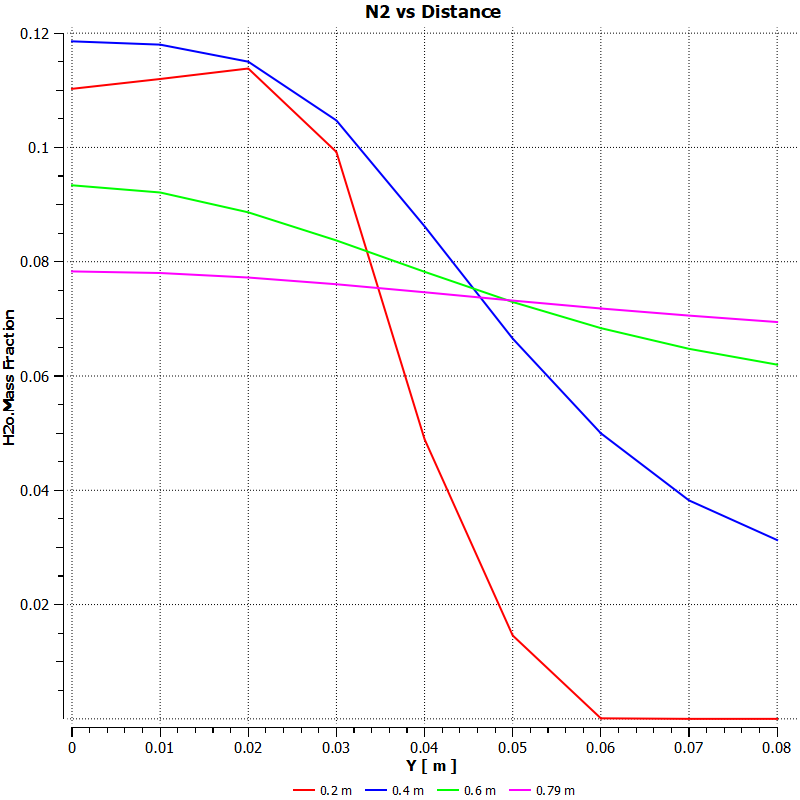

Perform a combustion simulation on the combustor model and plot the variation of the mass fraction of the different species in the simulation using line probes at different locations of the combustor as shown in Fig. You need to plot for CO2, H2O, CH4, N2, O2, NOx emissions & Soot formation.

Part II

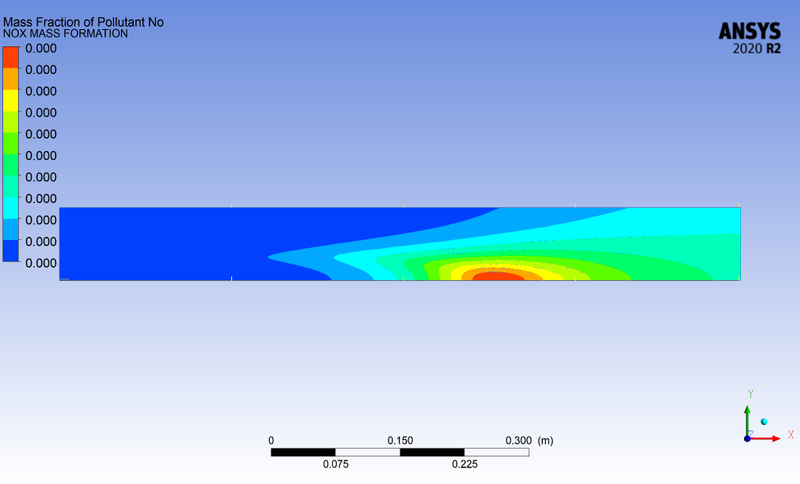

As you must have observed from the above simulation, the Nox and soot is getting formed at the outlet of the combustor. Such formation has harmful effects on the environment and humans. The stringent government norms also demand the least formation of Nox and soot and to satisfy those requirements, you need to check the effect of adding the water in the fuel.

In this part, you need to add the water content in the fuel from 5% to 30% by mole and observe the effect of it on the results. It is necessary to provide line plots and contours to prove your claim

Theory:-

Combustion is a fundamental process that is required to move any mechanical system. It can be defined as the process in which chemical energy is converted into heat energy. It contains a fuel and an oxidizer ( solid, liquid or gas but usually gas). For example an IC engine is a machine that converts the stoichometric mixture of fuel ( gasoline ) and Air to heat energy which can generate the required motion. In layman's term burning fuel is combustion. During the process of combustion some by products are obtained due to the chemical reaction between fuel and oxidizer. This can generate certain flue gases that can have ramifications on nature and hence it is necessary to select the proper stoichiometric ratio of fuel and oxidizer so that minimal fuel gases can be released. Pollutants such as NOx, SOx, Co2, Co are some major green house gases that can deplet the ozone layer and are harmful to the nature.

Introduction and pre processing :- The CAD model was provided in which the simulation for the aforementioned tasks were accomplished. In order to make the simulation easier the 2-d model was made and simulation was performed. The image is mentioned below.

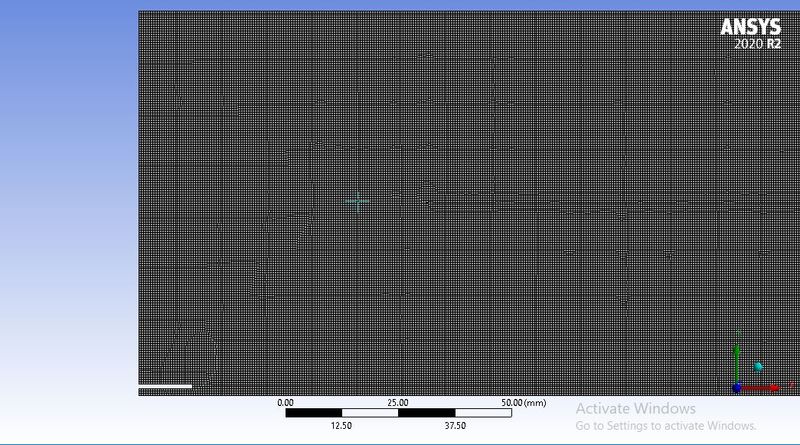

After the successful completion of model the model was meshed in ansys 2020 r2. The min. mesh size was 0.5 mm that concluded approx 2.7 lakh nodes. Further details are mentioned below.

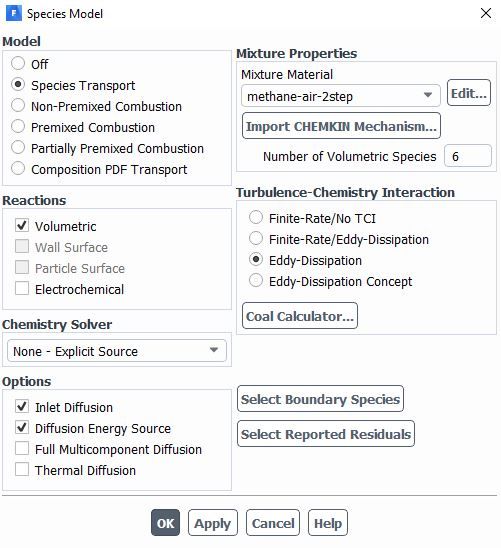

Solving:-Steady-state k epsilon model with Pressure-based solver and coupled scheme was used with axisymmetric model and gravity disabled to solve the simulation. The images are further attached for reference. The species model was enabled and the content of water was varied from 5 % to 30 % (task 2) of the simulation. In order to accomplish it a parametric study was done.

In the task one all the parameters were same as mentioned above and the only change was the material was methane (without water content). The meshing was same in the following task.

Post Processing:-

The following results were found

Task 1:- Air + methane (without water).

Task 2:- Methane + water

| Name | P7 - ch4 | P8 - h20 | P10 - mass-fraction-o2-op | P11 - mass-fraction-co2-op | P12 - mass-fraction-co-op | P13 - mass-fraction-n2-op | P14 - mass-fraction-water-op | P15 - mass-fraction-methane-op | P16 - temperature-op | Mass fraction of NOX | Mass fraction of SOOT |

| Units | C | ||||||||||

| Task 1 | 1 | 0 | 0.14053795 | 0.057012289 | 0.000714797 | 0.75214867 | 0.000714797 | 0.001991191 | 867.319 | 7.98635e-05 | 0.00357849 |

| Task 2 | 0.95 | 0.05 | 0.14365145 | 0.054963075 | 0.000622131 | 0.75207339 | 0.000622131 | 0.001727634 | 840.1512 | 6.41157e-05 | 0.00264061 |

| Task 2 | 0.9 | 0.1 | 0.14690415 | 0.052805178 | 0.00054113 | 0.75198399 | 0.00054113 | 0.00149848 | 811.3967 | 5.04044e-05 | 0.00204627 |

| Task 2 | 0.85 | 0.15 | 0.15030159 | 0.05054006 | 0.00046629 | 0.75190156 | 0.00046629 | 0.001288252 | 781.0435 | 3.8545e-05 | 0.00152345 |

| Task 2 | 0.8 | 0.2 | 0.1538353 | 0.048174533 | 0.000397752 | 0.75182264 | 0.000397752 | 0.001096619 | 749.1525 | 2.85664e-05 | 0.00111615 |

| Task 2 | 0.75 | 0.25 | 0.15750297 | 0.0457103 | 0.000335498 | 0.75174765 | 0.000335498 | 0.000923272 | 715.70898 | 2.0418e-05 | 0.000807817 |

| Task 2 | 0.7 | 0.3 | 0.16130101 | 0.043149924 | 0.000279487 | 0.75167688 | 0.000279487 | 0.000767809 | 680.70646 | 1.39983e-05 | 0.000591145 |

With addition of water there was dramatic reduction in the SOOT and NOx formation. This also led to reduction in temperature generation which is a critical parameter in combustion.

Results and Discussion: It is obvious that with increase in water content there was reduction in the formation of NOx and SOOT but at the same time there was significant drop in the temperature, which can be called as one of the disadvantages.

Results and Discussion: It is obvious that with increase in water content there was reduction in the formation of NOx and SOOT but at the same time there was significant drop in the temperature, which can be called as one of the disadvantages.

The decreasing trend indicates the reduction in SOOT and NOX formation with increase in mass fraction of water. However the rate at which the reduction takes place for each gas is different, it is least for CO2 whereas for other gases it is almost the same. Alternatively with increase in water content all the flue gases (Co2, Co etc) were reducing. However the effect of increase in water content on the quality of energy being released needs to be seen which is not covered in this task.

Leave a comment

Thanks for choosing to leave a comment. Please keep in mind that all the comments are moderated as per our comment policy, and your email will not be published for privacy reasons. Please leave a personal & meaningful conversation.

Other comments...

Be the first to add a comment

Read more Projects by mohit tiwari (9)

Week 10 - Simulating Combustion of Natural Gas.

The following objectives were undertaken during this project:- Part I Perform a combustion simulation on the combustor model and plot the variation of the mass fraction of the different species in the simulation using line probes at different locations of the combustor as shown in Fig. You need to plot for CO2,…

13 Apr 2021 10:02 AM IST

Gate Valve Parametric Study

A valve is a simple mechanical or electro-mechancial device that can help to regulate, control and direct the flow of fluid by opening it completly or partially. The classification of valves based on their use is vast. The selection of appropriate valve in HVAC, REFRIGERATION and piping industry is of prime importance…

15 Dec 2020 05:02 AM IST

Cyclone Separator Challenge

Cyclone Seperator is a device that is used to seperate the dust particles from the air. or gas They simply employ centrifugal force of the spinning gas to seperate the dust from the cariier gas. Cyclone seperators are well suited for high temperature and pressure conditions because of the robust design it has. The efficiency…

17 Nov 2020 09:19 AM IST

Conjugate Heat Transfer Analysis on a graphics card.

The following work has been performed on SpaceClaim, Fluent meshing, Gambit meshing and ANSYS Fluent. Graphics Card is one of the crucial component on PC/Laptop to perform critical tasks. With recent advancements in the technology to perform the analysis the smaller the the card the compact the system. The higher…

15 Sep 2020 05:10 AM IST

Related Courses

0 Hours of Content

Skill-Lync offers industry relevant advanced engineering courses for engineering students by partnering with industry experts.

Our Company

4th Floor, BLOCK-B, Velachery - Tambaram Main Rd, Ram Nagar South, Madipakkam, Chennai, Tamil Nadu 600042.

Top Individual Courses

Top PG Programs

Skill-Lync Plus

Trending Blogs

© 2025 Skill-Lync Inc. All Rights Reserved.