Courses by Software

Courses by Semester

Courses by Domain

Tool-focused Courses

Machine learning

POPULAR COURSES

Success Stories

Cyclone Separator Challenge

Aim:- To perform analysis on cyclone separator and calculate the separation efficiency and pressure drop. Objective: To study different empirical models used to calculate the cyclone separator efficiency. To perform an analysis on the cyclone separator model and understanding its working. To understand…

Vishavjeet Singh Yadav

updated on 10 Sep 2020

Aim:- To perform analysis on cyclone separator and calculate the separation efficiency and pressure drop.

Objective:

- To study different empirical models used to calculate the cyclone separator efficiency.

- To perform an analysis on the cyclone separator model and understanding its working.

- To understand the effects of velocity and particle size (dia on cyclone separator efficiency and pressure drop.

Introduction

Cyclone separators are separation devices (dry scrubbers) that remove particulate matter from flue gases by using the principle of inertia. Cyclone separators are one of many air pollution control devices known as pre-cleaners since they generally remove larger pieces of particulate matter. This prevents finer filtration methods from having to deal with large, more abrasive particles later on. In addition, several cyclone separators can operate in parallel, and this system is known as a multi-cyclone.

Working

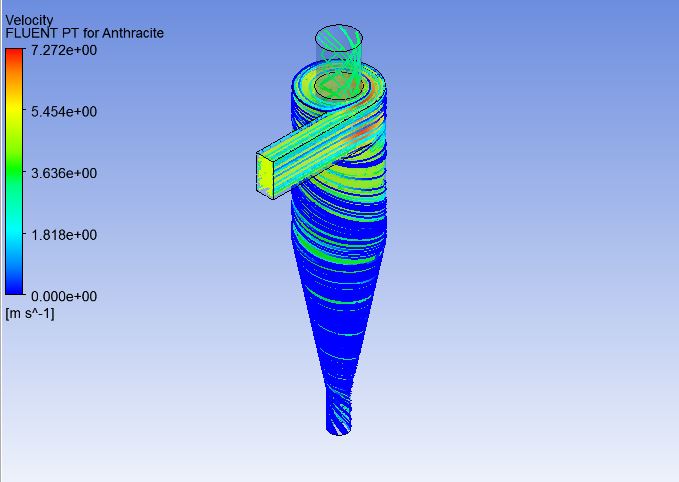

Cyclone separators work much like a centrifuge, but with a continuous feed of dirty air. In a cyclone separator, dirty flue gas is fed into a chamber. The inside of the chamber creates a spiral vortex, similar to a tornado. This spiral formation and the separation are shown in the Figure shown below. The lighter components of this gas have less inertia, so it is easier for them to be influenced by the vortex and travel up it. Contrarily, larger components of particulate matter have more inertia and are not as easily influenced by the vortex.

Since these larger particles have difficulty following the high-speed spiral motion of the gas and the vortex, the particles hit the inside walls of the container and drop down into a collection hopper. These chambers are shaped like an upside-down cone to promote the collection of these particles at the bottom of the container. The cleaned flue gas escapes out the top of the chamber.

Most cyclones are built to control and remove particulate matter that is larger than 10 micrometers in diameter. However, there do exist high-efficiency cyclones that are designed to be effective on particles as small as 2.5 micrometers. As well, these separators are not effective on extremely large particulate matter. For particulates around 200 micrometers in size, gravity settling chambers or momentum separators are a better option.

Out of all of the particulate-control devices, cyclone separators are among the least expensive. They are often used as a pre-treatment before the flue gas enters more effective pollution control devices. Therefore, cyclone separators can be seen as "rough separators" before the flue gas reaches the fine filtration stages.

Effectiveness

Cyclone separators are generally able to remove somewhere between 50-99% of all particulate matter in the flue gas. How well the cyclone separators are actually able to remove this matter depends largely on particle size. If there is a large amount of lighter particulate matter, less of these par0ticles are able to be separated out. Because of this, cyclone separators work best on flue gases that contain large amounts of big particulate matter.

There are several advantages and disadvantages of using cyclone separators. First, cyclone separators are beneficial because they are not expensive to install or maintain, and they have no moving parts. This keeps maintenance and operating costs low. Second, the removed particulate matter is collected when dry, which makes it easier to dispose of. Finally, these units take up very little space. Although effective, there are also disadvantages in using cyclone separators. Mainly because the standard models are not able to collect particulate matter that is smaller than 10 micrometers effectively and the machines are unable to handle sticky or tacky materials well.

Different Empirical models used for cyclone separator efficiency:

4.1. Iozia and Leith Model

- The tangential velocity of a particle is equal to the tangential velocity of the gas flow, i.e. there is no slip in the tangential direction between the particle and the gas.

- The tangential velocity is related to the radius of cyclone by: =constant.

| Particle Size | 1 | 2 | 3 | 4 | 5 |

| Particle Time |  |

|

|

|

|

| Particle Size | Tracked | Escaped | Trapped | Incomplete | Efficiency |

| 1 | 576 | 266 | 301 | 9 | 0.522 |

| 2 | 576 | 245 | 329 | 2 | 0.571 |

| 3 | 576 | 202 | 374 | - | 0.649 |

| 4 | 576 | 189 | 387 | - | 0.671 |

| 5 | 576 | 166 | 410 | - | 0.712 |

| Particle Velocity | 1 m/s | 2 m/s | 3 m/s | 4 m/s | 5 m/s |

| Particle Time |  |

|

|

|

|

| Pressure |  |

|

|

|

|

| Velocity |  |

|

|

|

|

| Vortex |  |

|

|

|

|

| Particle Velocity | Tracked | Escaped | Trapped | Incomplete | Pressure at Inlet [Pa] | Pressure at Outlet-1 | Pressure at Outlet-2 | Total Pressure Drop | Efficiency |

| 1 m/s | 576 | 220 | 240 | 116 |

2.36565 |

0.1901 | 0.3571 | 1.87855 | 0.416667 |

| 2 m/s | 576 | 183 | 385 | 8 |

9.89978 |

0.7815 | 1.2726 | 8.62716 | 0.6684 |

| 3 m/s | 576 | 137 | 439 | - |

11.9642 |

1.6573 | 2.3941 | 9.5701 | 0.76215 |

| 4 m/s | 576 | 95 | 481 | - | 18.6148 | 3.0441 | 4.1623 | 14.4525 | 0.8351 |

| 5 m/s | 576 | 58 | 518 | - |

34.0316 |

4.3134 | 5.8386 | 28.193 | 0.8993 |

Leave a comment

Thanks for choosing to leave a comment. Please keep in mind that all the comments are moderated as per our comment policy, and your email will not be published for privacy reasons. Please leave a personal & meaningful conversation.

Other comments...

Be the first to add a comment

Read more Projects by Vishavjeet Singh Yadav (20)

Week 5.2 - Literature review: ODE Stability

AIM: To understand the stability of an ODE and its effect on engineering simulation. Ordinary Differential Equation: It contains derivatives of one or more functions of an Independent variable. We need to determine the function or set of functions that satisfy the equation to solve an ODE. When does a ODE become…

29 Jan 2022 12:30 PM IST

Week 5.1 - Compact Notation Derivation for a simple Mechanism

AIM: Derive the compact Notation of simple Mechanism. Reaction Mechanism: In chemical kinetics, we use measurement of the macroscopic properties like,rate of change in the concentration of reactants or products with time, to discover the sequence of events that occur at the molecular level during a reaction. This…

21 Jan 2022 11:06 AM IST

Week 4.2 - Combustion Efficiency Calculation after Preheating

AIM To calculate the combustion efficiency after Preheating. OBJECTIVES Find the effect of the range of inlet air preheating from 298k to 600k on the adiabatic flame temperature. Find the effect of pre-heating temperature on combustion efficiency. Theory A Recuperator is often used in power engineering…

17 Jan 2022 11:14 AM IST

Week 4.1- Handling Mixtures with Cantera

AIM To work on the quantity class of the Cantera to create various mixtures. Objective Perform calculation of the adiabatic flame temperature of a gas mixture using quantity class. 1) Use the "moles" method/function of the A object(air) and explain how it was calculated. Now consider any hydrocarbon…

20 Apr 2021 07:08 PM IST

Related Courses

0 Hours of Content

Skill-Lync offers industry relevant advanced engineering courses for engineering students by partnering with industry experts.

Our Company

4th Floor, BLOCK-B, Velachery - Tambaram Main Rd, Ram Nagar South, Madipakkam, Chennai, Tamil Nadu 600042.

Top Individual Courses

Top PG Programs

Skill-Lync Plus

Trending Blogs

© 2025 Skill-Lync Inc. All Rights Reserved.