PRABHAT RANJAN KUMAR

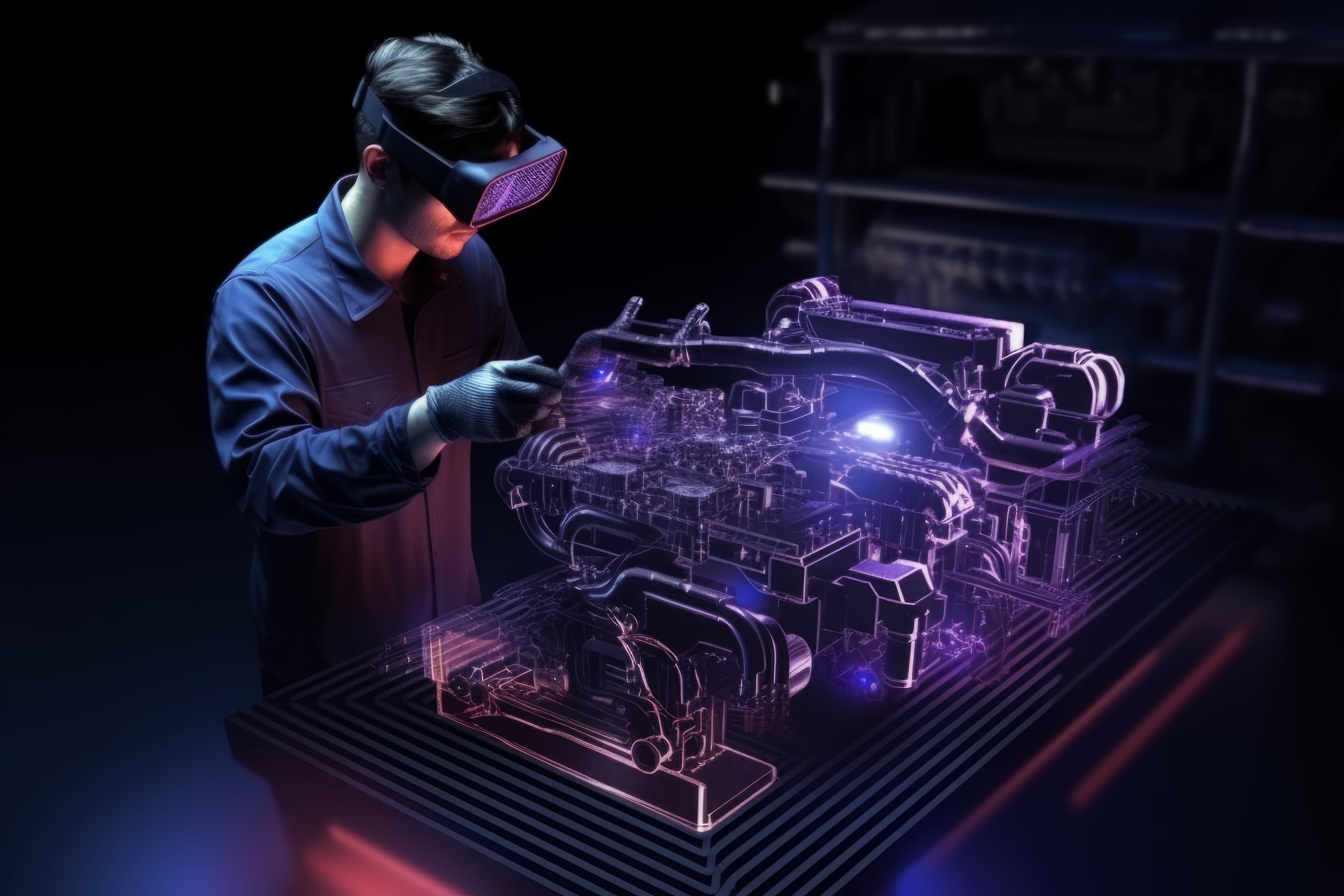

Master Certification In Computationa Fluid Dynamic

Skills Acquired at Skill-Lync :

- CFD

- NUMERICAL-ANALYSIS

- MATLAB

- OPENFOAM

- STRUCTURAL-MESHING

- ANSA

- ANSYS-FLUENT

- COMBUSTION

Introduction

25 Projects

Tool Test 1

AIM:-Take the mid surface of the given component and mesh the surface according to the given quality criteria. Procedure for taking the mid surface 1.Open the given model in ansa and applt TOPO. 2. Check the geometry error if found any error remove the error using delete release and paste command and fix some error.…

14 Mar 2020 04:58 AM IST

Simulation over Ahmed body

Aim:- Perform a grid independency test over the given ahmed body in Ansys fluent. Objective- use the \'split body\' command in SpaceClaim to perform the operation and then you can use the symmetry boundary condition in fluent to perform the simulation. Run the simulation for the velocity of 25 m/sec with the…

05 May 2020 06:36 AM IST

project 1

AIM:- Extract the mid surface ,Generate the mesh flow within the quality parameters of given IP substrate. 1.Open the given model in ANSA and check the geometrical error, remove and fix the geometrical error using topo, delete, release and paste option. 2.Extraction of mid surface First check the thickness…

07 Apr 2020 09:09 AM IST

Mixing efficiency

Aim:- steady-state simulations to compare the mixing effectiveness when hot inlet temperature is 360C & the Cold inlet is at 190C using Ansys Fluent. Objective 1. To setup the steady state simulation and compare the mixing effectiveness. 2. Use the k-epsilon and k-omega SST model for the first case and based on your…

16 Apr 2020 08:23 AM IST

To extract mid surface and create mesh in the bottle cap according to the given quality criteria by ANSA

Aim :-To extract mid surface and create mesh in the bottle cap according to the given quality criteria by ANSA. Procedure The given component is a bottle cap . This bottle cap is plastic part and so that thickness is very low, so instead of 3D meshing wo can go for 2D meshing. For that we need to extract the mid…

04 Mar 2020 08:49 AM IST

project 2

Aim:-For the given Rear suspension , check for the geometrical errors and meshand apply connection with the given element Quality criteria. Procedure 1. First open the given rear suspension system in Ansa apply Topology and check the geometrical error of the given component. 2. Given suspension system is broken in…

13 Apr 2020 09:13 AM IST

Flow over cylinder

Aim:- Steady and transient flow simulations of flow over a cylinder, explain the phenomenon of Karman vortex street PART-I Simulate the flow with the steady and unsteady case and calculate the Strouhal Number for Re= 100. PART-II Calculate the coefficient of drag and lift over a cylinder by setting the Reynolds number…

28 Apr 2020 01:54 AM IST

MORPHING

Aim:- Morph the given component using morphing module in ANSA Morphing Morphing is the process of change the shape and design terminology of the given component without any numericcal input. The functions of the Morphing menu can be used to efficiently re-shape both FE and/or Geometry based models. Domain (Box) Morphing…

05 Apr 2020 11:55 PM IST

connection of rear door model

AIM:- Make the connection of rear door model. Tool used for making the connection of rear door model. 1. First open the given the .nas file in ANSA and check the geometry. 2. Assign the given model small component in to different PID. 3. Now check the given model for which…

22 Mar 2020 11:59 AM IST

Rearview Mirror

AIM:-check for the geometrical errors and mesh the element with given Quality criteria. Geometry elimination method: 1.Open the model then apply topo 2.Eliminate all the errors using hot point,cons and faces which is in topo module. 3.In mesh module set the length and micro area accorging to the given…

14 Mar 2020 05:38 AM IST

Tool Test 2

Aim:- To perform a volume mesh for the given component under given quality criteria. Import the given intake manifold.igs Cleanup geometry 1. Apply toppo 2.Under mesh module change perimeter length and micros 1mm 3. Check the geometry for errors, error like triple cons ,Needle faces…

15 Mar 2020 12:46 AM IST

Exhaust port

Aim: Perform a CHT analysis with the k-epsilon and k-omega SST model and explain which one is best refined & best possible mesh on an exhaust manifold. Objective:- Show the velocity, temperature, and heat transfer coefficient plots and explain it. Exhaust manifold In automotive engineering, an exhaust manifold collects…

15 May 2020 05:26 AM IST

Conjugate Heat Transfer Analysis on a graphics card.

AIM:- Perform the simulation of a steady state conjugate heat transfer of two different mesh size on a given graphics card. Objective:- 1. Find out the maximum temperature attained by the processor. 2. Prove that the simulation has achieved convergence with appropriate images and plots. 3. Find out the heat transfer coefficient…

18 May 2020 05:36 PM IST

Rayleigh Taylor Instability Challenge

AIM:- Perform the Rayleigh Taylor instability simulation for 2 different mesh sizes with the base mesh being 0.5 mm. Compare the results by showing the animations and Run one more simulation with water and user-defined material(density = 400 kg/m3, viscosity = 0.001 kg/m-s) for refined mesh. Find out the…

25 May 2020 11:25 AM IST

Cyclone Separator Challenge

Aim:- To perform analysis on cyclone separator and calculate the separation efficiency and pressure drop. Objective:- To write a few words about any four empirical models used to calculate the cyclone separator efficiency. To perform an analysis on a given cyclone separator model by varying the particle…

12 Jun 2020 07:38 AM IST

gearbox simulation

Aim- Perform the 2D simulation of the Gearbox for the given four cases and compare the result among all the four cases. Part 1: 20% Immersion, Fluid - Engine oil. 30% Immersion, Fluid- Engine oil. 20% Immersion,Fluid-n-heptane (c7h16). 30% Immersion,Fluid-n-heptane (c7h16). Part 2: What is Dynamic meshing? Give some other…

15 Jun 2020 01:12 PM IST

Gate Valve Parametric Study

Aim:- Perform a parametric study on the gate valve simulation by setting the opening from 10 % to 80%. Obtain the mass flow rates at the outlet for each design point. Calculate the flow coefficient and flow factor for each opening and plot the graph. Discuss the results of the mass flow rate and flow coefficient. …

16 Jun 2020 01:10 PM IST

Challenge on Combustion

Aim:- Perform a combustion simulation on the combustor model and plot the variation of the mass fraction of the different species. Introduction Combustion models for CFD refers to combustion models for computational fluid dynamic. Combustion is defined as a chemical reaction in which a hydrocarbon fuel reacts…

21 Jun 2020 01:05 PM IST

Week 4: Project - Steady state simulation of flow over a throttle body

Aim :- Flow over a throttle body using steady state simulation. Objective 1.Post process the results and show pressure and velocity contours. 2.Show the mesh (i.e surface with edges) 3.Show the plots for pressure, velocity, mass flow rate and total cell count. 4.Create an animation in which it throttle movement should…

21 Jul 2020 05:53 AM IST

Week 4: Project - Transient simulation of flow over a throttle body

Aim :- Transient simulate the flow through a throttle body through 25 degree angle of rotation of the throttle plate with time. Introduction A throttle valve is integral part of the IC engine and is basically used to control the engine speeds. It consist of a throttle plate that is connected to actuators which is…

24 Jul 2020 07:25 AM IST

Week 5: Prandtl Meyer Shock problem

Aim:- To simulate the prandtl mayer shock problem and steady the Effect of SGS parameter on shock location an cell count. Shock Flow Boundary Conditions: For solving the steady state flow appropriate boundary conditions are needed. It is one of the required components of the mathematical…

29 Jul 2020 02:33 PM IST

Week 6: Conjugate Heat Transfer Simulation

Objective :- Setup the baseline simulation flow through the pipe ,check the grid dependence test by varying grid size according to the given reynolds number 7000. Also compare the result of supercyle stage interval to 0.01,0.02 and 0.03 with baseline simulation. Introduction The term conjugate heat transfer (CHT) is used…

04 Aug 2020 04:58 PM IST

Week 7: Shock tube simulation project

Aim:- Setup a transient shock tube simulation plot the pressure and temperature in the entire domain. Introduction Shock tube are the device which is used to study chemical kinetics. Shock tube consists of two chambers and a diaphargm which seperates the two chambers. One side is the high pressure gas other side is…

09 Aug 2020 06:36 PM IST

Week 8: Literature review - RANS derivation and analysis

Aim:- Apply reynold's decomposition to the NS equations and evaluate the expression for reynold's stress, also explain the term reynolds stress. What…

16 Aug 2020 11:11 AM IST

Week 10: Project 1 - FULL HYDRO case set up (PFI)

Objective:- 1. Perform the no hydro simulation in a Port Fuel Injection engine examine the valve and the piston movement. 2. Perform the full hydro simulation of the engine and study the spray parcel distribution and flame propgation of the engine. 3.Find the compression ratio , power, torque, combustion efficiency…

27 Sep 2020 09:50 AM IST

4 Course Certificates

Advanced CFD for IC Engine Applications using CONVERGE

15 Workshop Certificates

Introduction and Application of CAE in different physics domain

How to build a world-class amusement park as a Mechanical Engineer

Academic Qualification

M.Tech

ANNAMALAI UNIVERSITY

14 Jul 2008 - 11 May 2012

10th

s g d patliputra patna

05 Apr 2004 - 14 Apr 2008

12th

COLLEGE OF COMMERCE PATNA

05 Jul 2005 - 16 Jul 2007

Here are the courses that I have enrolled

Similar Profiles

Ladder of success cannot be climbed with hands in pocket.

The Future in Motion

Give more than what you get you will get more than what you gave

Avid learner