Modified on

08 Aug 2022 07:35 pm

Which Mechanical Design Engineering Skills Look Best in Your Resume?

Skill-Lync

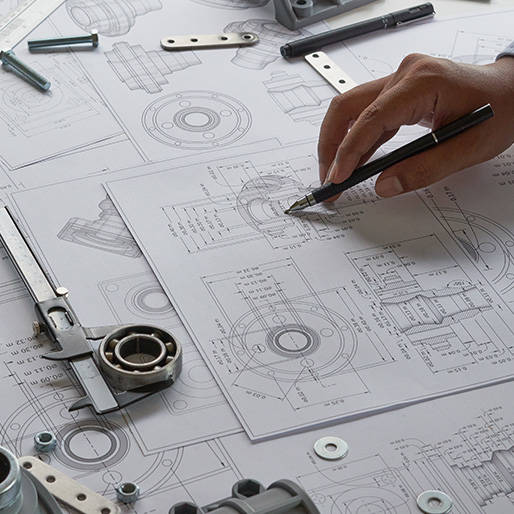

If you think having a basic knowledge of maths and technology and being creative and solution-oriented is enough to secure a job in mechanical design engineering, you are only at the base of the mountain. This blog on being a good mechanical design engineer will inform you of the skills you must acquire to boost your resume.

1. CAD Software Skills

Here’s what you can do to gain skills in CAD —

- Learn at least one popular and advanced CAD software program like CATIA, NX CAD, SOLIDWORKS, Pro-Engineer, etc.

- Demonstrate new components or assemblies, virtual mock-ups, and PoCs of existing designs to showcase mechanical improvements with reduced costs.

- Strengthen the basic drafting standards like ANSI/ASME Y14.

- Develop a detailed drawing of heavy equipment with CTF dimensions using a 3D CAD model for concept visualisation, remote material handling for manufacturing, animation, etc.

- Analyse CAD systems for greater efficiency, outsourcing of components, creation of Bill of Materials (BoM), etc.

2. Finite Element Analysis (FEA) Software Skills

Learn FEA the following way

- Learn the basics of FEA for the design of vibrations and stress with engineering calculations.

- Create analysis with FEA tools and design worksheets.

- Study FEA solutions like pre and post-processing software like ANSA, FEMGEN, PATRAN, and solvers like ABAQUS, NASTRAN, SAMCEF, etc.

- Demonstrate FEA evaluations of assemblies and components with FEA software to showcase the reliability and durability predictions of the product.

3. CREO CAD Software Skills

If you want to become a mechanical design engineer in India, acquiring the following skills in CREO CAD would be beneficial -

- Creating 2D orthographic production drawings with CREO CAD 2.0 for universal satellite integration work or sheet metal radiation shielding panels.

- Creating product assemblies with CREO 2.0.

- Developing 3D CAD and 2D drawings with 3D CAD Pro Engineering Software.

4. Product Design Skills

This includes creating basic design ideas that are used before mass production. You can learn the following product design skills:

- Learn to monitor and coordinate all stages of product designs, from selection and manufacturing to fabrication and operation.

- Oversee customer-driven changes, configuration management, certificate compliance, design improvements, etc.

- Create a novel vacuum platform prototype with an improvement in current product designs for new customer applications.

5. Layout Skills

Learn the following layout skills —

- Understand the heating and cooling load calculation with a selection of proper equipment and HVAC system layout.

- Study structural steel layout for hanging structures, conveyor installation, etc., manufacturing layout for assembly fixtures, standard quality requirements, etc.

6. Automotive Sketching Skills

Every mechanical design engineer must learn highly technical engineering drawings that demonstrate important details of components, types of equipment, etc. You can learn the following to develop advanced engineering sketching skills -

- Learn orthographic, isometric, multiview, and schematic drawings to showcase the product from all views.

- Develop product drawings of different shapes for interior component specifications, labelling, etc.

- Create interior and exterior product sketches to demonstrate enhanced dimensions and increased performance.

In addition, developing problem-solving, communication, math, engineering design and design review skills will help you become efficient in your role as a mechanical design engineer.

How to Become a Mechanical Design Engineer?

The application of CAD software in design has improved design quality by reducing processing time, product costs and risks. Hence learning CAD is the first step to becoming a design engineer.

Skill-Lync can help you become a design engineer with its Post Graduate Program in CAD. This course equips you with -

- 35 comprehensive industry projects

- Software skills for SOLIDWORKS User Interface

- Advanced sketching and solid modelling skills

- Rendering and assembly techniques skills

- Surface modelling skills

- Seating, lighting, BIW fixture design, wiring harness skills with CATIA V5

- Class A surfacing skills with ALIAS

- Metal designing skills with Siemens NX CAD

Job Opportunities for Mechanical Design Engineers

Mechanical design engineering is not only an ambitious and competitive sector but is also in great demand today. Some of the jobs that you can acquire with the skills mentioned above are —

- Plastic Design Engineer

- Sheet Metal/ BIW Design Engineer

- Product Design Engineer

- Design and Release Engineer (D&R)

- Wiring Harness Engineer/ Designer

- Seating Design Engineer

Conclusion

A degree in mechanical engineering will provide you with hard skills such as an aptitude for mathematics, computer design, simulation, etc. However, having a couple of soft skills up your sleeve is also important. Your resume and cover letter should demonstrate a strong set of hard and soft skills to help you succeed in your interview and secure your desired job.

Author

Anup KumarH S

Author

Skill-Lync

Subscribe to Our Free Newsletter

Continue Reading

Related Blogs

Learn how to render a shock-tube-simulation and how to work on similar projects after enrolling into anyone of Skill-Lync's CAE courses.

10 May 2020

In this blog, read how to design the frontal BIW enclosure of a car (Bonnet) and learn how Skill-Lync Master's Program in Automotive Design using CATIA V5 will help you get employed as a design engineer.

10 May 2020

Tetrahedral is a four- nodded solid element that can be generated through the tria element by creating a volume and also through the existing volume of the geometry. These elements are used where the geometry has high thickness and complexity. The image attached below is a representation of a Tetra element. The Tetra element will have 4 triangular faces with four nodes joining them together

02 Aug 2022

A connector is a mechanism that specifies how an object (vertex, edge, or face) is connected to another object or the ground. By often simulating the desired behaviour without having to build the precise shape or specify contact circumstances, connectors make modeling simpler.

03 Aug 2022

One of the most crucial processes in carrying out an accurate simulation using FEA is meshing. A mesh is composed of elements that have nodes—coordinate positions in space that might change depending on the element type—that symbolise the geometry's shape.

04 Aug 2022

Author

Skill-Lync

Subscribe to Our Free Newsletter

Continue Reading

Related Blogs

Learn how to render a shock-tube-simulation and how to work on similar projects after enrolling into anyone of Skill-Lync's CAE courses.

10 May 2020

In this blog, read how to design the frontal BIW enclosure of a car (Bonnet) and learn how Skill-Lync Master's Program in Automotive Design using CATIA V5 will help you get employed as a design engineer.

10 May 2020

Tetrahedral is a four- nodded solid element that can be generated through the tria element by creating a volume and also through the existing volume of the geometry. These elements are used where the geometry has high thickness and complexity. The image attached below is a representation of a Tetra element. The Tetra element will have 4 triangular faces with four nodes joining them together

02 Aug 2022

A connector is a mechanism that specifies how an object (vertex, edge, or face) is connected to another object or the ground. By often simulating the desired behaviour without having to build the precise shape or specify contact circumstances, connectors make modeling simpler.

03 Aug 2022

One of the most crucial processes in carrying out an accurate simulation using FEA is meshing. A mesh is composed of elements that have nodes—coordinate positions in space that might change depending on the element type—that symbolise the geometry's shape.

04 Aug 2022

Related Courses